Autonomous Robot Path Planning and Internet of Things-Juniper Publishers

Juniper Publishers Journal of Robotic Engineering

Abstract

Robotics is known as a new revolution to the entity

of beings that varies according to its uses. In modern day environments,

robotics and automation are involved in almost every industrial

activity and conveniently improve the efficiency, productivity and

reliability of a system. Autonomous Guided Robot (AGR) systems are

classified as rover based robotics that require vision type and touch

sensors. The AGR should be able to maneuver and counteract with the

environment using sensors to detect the obstacles around, remember its

current position and calculate a new path to take. Robotics Automation

with industrial robots in combination with Internet of things, the birth

of intelligent flexible automation systems, with the technical

advantages of intelligent flexible automation systems, the company

recently signed several million more than the contract, industry all

over the hot die forging automation, automation of internal combustion

engines, engine Assembly, automotive automatic battery swap station and

so on. Thus, in this paper an over view of the significance of path

planning and internet of robotic things is presented.

Keywords: Industrial robot; path planning; Internet of things (IoT)

Introduction

Robotics is implemented in medical practice,

construction, outer-space exploration, household assistance, mobile

transportation and quite recently, under water exploration [1-3].

Currently there has been study of automated guided robots which is used

in transportation and exploration that can be configured for different

terrain. These designs are onlocomotion, Hopfield Neural Network,

Genetic Algorithm and etc [4-6].

For example, JPL (Jet PropulsionLaboratory, NASA) in U.S.A have

developed many rovers. Sojourner which were landed in Mars in 1997

adopted rocker-bogie locomotion, Blue Rover uses three-segment

locomotion, the mini Mars rover Go-For has an active wheel-legged

locomotion, Nano Rover utilize posable tructchassis and Elastic Loop

Mobility System was also designed as new type of locomotion for

planetary exploration [7].

Robot Path Planning or robot Motion Planning is one

of the important areas of interest in robot's offline decision making

algorithms. In this problem, the aim is to find a collision free path,

which the robot can follow to reach the target from its start position.

Analysis and research on autonomous path planning has included

innovative advancements in the use of artificial intelligence (AI). With

advancement in the study of this subject, technology with

uncontrollable situations such as outer space exploration and deep sea

excavation can be further improved. New technology such as autonomous

vehicle systems may also beable to utilize such algorithms which are

fail-safe. With sensors, robots are said to be able to obtain vision,

sense of touch, balance, and even hearing. According to their tasks and

application, robots are given the appropriate sensors that function as

the feedback systems in a controller [8].

Once the collision-free configuration space is

described asa graph, the shortest path between two nodes can be searched

.An overview about common path finding algorithms is given in [9]

depth-first, breadth-first and best-first search, the algorithm of

Dijkstra and finally the A* algorithm. All these approaches find a

solution, if one exists. Especially the Dijkstra and A*algorithm are in

the focus of research [10],

as they promise theoptimal path with a minimal computing time. The

algorithm of Dijkstra was developed in 1959 and always finds the

shortest path between two given nodes or proves that no solution exists [11].

For this purpose, the costs g(n) fromthe start node is assigned to each

considered node n. There by the nodes with the smallest value of g(n)

are prioritized which guarantees an optimal path.

On this basis, the widely used A* algorithm was presented in 1968 [12].

The method finds a least-cost path between astart and a goal node. This

is achieved by evaluating a cost function f(n) of a node n to determine

in which sequence the search visits nodes in order to expand the fewest

possible nodes. The function f(n) is the sum of the known costs g(n)

from the start node to n and the estimated costs h(n) (also called

heuristic function) from n to the goal node. The A* algorithm is

complete it will always find a solution if one exists. Furthermore it

computes the optimal path if the heuristic h(n) does not over estimate

the costs to the goal and is faster than the algorithm of Dijkstra [13].

For a robot with m joints, the configuration space is

an m dimensional space spanned by the degrees of freedom of the robot

system and sub divided in collision-free regions. Based on this

configuration space movements of the robot can be determined. Assuming a

six dimensional standard industrial robot, the discretization of the

space according to collisions would be a time consuming process.

Consequently, an effective method for building a collision-free

configuration space is needed.

Robotic system has brought tremendous changes in various socio-economical aspects of human society during the past decades [14].

Industrial robot manipulators have been widely deployed and used in all

sorts of industries to perform repetitive, tedious, critical, and/or

dangerous tasks, such as product assembly, car painting, box packaging,

and shield welding. These preprogrammed robots have always been very

successful at their accomplishments in several structured industrial

applications due to their high accuracy, precision, endurance, and

speed. Robotic technologies have been integrated with existing network

technologies to extend the range of functional values of these robots

when deployed in unstructured environments while fostering the emergence

of networked robotics during 90's [15].

The limitations have motivated the researchers to think of new form of

efficient robotic systems i.e., "Cloud Robotics”. Cloud robotics may be

described as a system that relies on the "Cloud Computing” [16] infra structure to access vast amount of processing power and data to support its operation [17]. That means not all sensing, computation, and memory is integrated into a single stand alone system as it was in case of networked robotics. Cloud Robotic

systems often include some portion of its capacity for local processing

for low-latency responses when network access is unavailable or

unreliable i.e., offline. One example of Cloud Robotics is the Google self-driving car

that indexes the Google maps, images, and other relevant information,

collected by the satellites and the crowd sourced Clouds to facilitate

accurate localization. Although, Cloud Robotics is benefited from

big data analytics, cloud computing, human computation, and

collaborative robot learning, it suffers from various issues such as

inter operability, heterogeneity, time- varying network latency,

security, multi-robot management, common infrastructure design,

Quality-of-Service (QoS), and standardization [17,18].

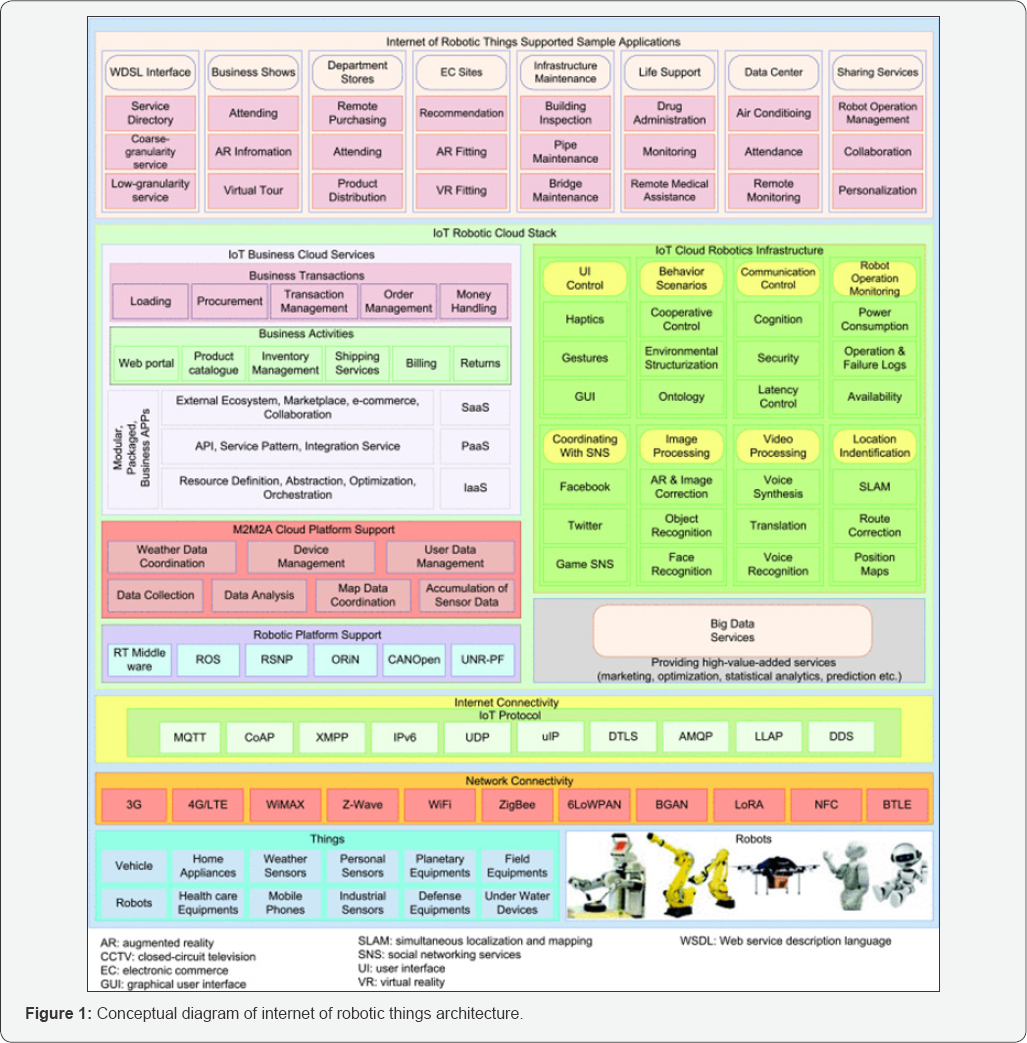

Due to the IoRT's inherent virtues of qualitative handling of mentioned

issues, it is envisaged that it will overcome these constraints,

leading to more intelligent, collaborative, heterogeneous, efficient,

self-adaptive, context aware, and yet cheaper robotic networks. An

architecture of robotic internet of things is shown in Figure 1.

In the developed world, automated production line

equipment for industrial robot automation equipment has become the

mainstream and the future direction of development. Foreign car

industry, electrical industry, engineering machinery industry has

extensive use of industrial robots, such as automated production lines

in order to guarantee the quality of products, to increase productivity,

while avoiding a large number of occupational accidents. Global

industrial robots used in many countries for nearly half a century of

experience has shown that the popularization of industrial robots are

automated production, improve production efficiency and effective means

of promoting enterprise and development of social productive forces.

Things with perception, information transmission, intelligence analysis

and decision making characteristics such as through perception,

equivalent to added features to industrial robots, vision, touch and

even taste through network messaging, smart analysis and decision,

equivalent to industrial robots human intelligence has given so that

robots can do most people is needed to complete the work.

Conclusion

Internet of Robotic Things allows robots or robotic

systems to connect, share, and disseminate the distributed computation

resources, business activities, context information, and environmental

data with each other, and to access novel knowledge and specialized

skills not learned by them, all under a hood of sophisticated

architectural framework. This opens a new horizon in the domain of

connected robotics that we believe shall lead to fascinating futuristic

developments. It indeed allows adapting into connected ecosystem where

resource constraint deployment of inexpensive robots shall be leveraged

by heterogeneous technologies, be it, communications network, processing

units, different genre of devices, or clouds services. Enormous

developments could be foreseen to get benefited from the IoRT approach

such, SLAM, grasping, navigation, and many more that are beyond the

discussion. In this paper, a novel Internet of Robotic Things

architecture is proposed considering conjugation between recently grown

IoT and robotics together.

For more open access journals please visit: Juniper publishers

For more articles please click on: Robotics & Automation Engineering Journal

Comments

Post a Comment