Research on Electromagnetic Driving Robot Fish-Juniper Publishers

Juniper Publishers-Journal of Robotics

Abstract

Based on the actual physical appearance of the tuna

and the wave equation derived from observing its swimming locomotion,

this paper proposes a new idea on the simulation and modeling of the

robot fish and a novel way of thinking on kinetic analysis. The motion

law for each joint of the robot fish was first obtained through the

discrete fitting method and the motion law was subsequently used as the

basis for the robot fish electromagnetic drive control signal. The

fluent flow field analysis software was utilized. The meshing of the

fluid around the fish body was performed by using the dynamic grid

technique. The surface pressure values of the fish body during the

steady state forward movement were analyzed, and the values of the

driving force of each part of the fish were obtained. It was then

determined that the electromagnetic drive caudal fin robot fish was the

optimal design. Based on the idea of digital-analog conversion, the

drive control signal waveform was digitally discretized, then the C51

single-chip microcomputer and DAC digital-to-analog converter was used

for conversion. The OPA544 op amp chip was then used to simulate the

amplified output in accordance with the control signal waveform.

Electromagnetic coil drive signal with variable frequency and voltage

can thus be achieved.

Keywords: Robot fish; Electromagnetic drive; Fluent flow field analysis; Kinetic analysis; Control signal; Swimming experiment

Construction of the Robot Fish Model

Determination ofthe external physical characteristics of the fish body and the number of joints

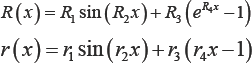

A real tuna fish was selected, the total length was

measured and the external curve of the fish body was fitted; the

following data can be obtained:

Total length l = 260mm

Where R(x) is the function of the longitudinal fish body curve, r(x) is the function of the transverse fish body curve

In the selection of the number of joints of the robot

fish, the higher the number of joints, the higher the degree of fit

between the swimming curve and the known fish body wave equation, the

closer it is to the real fish-swimming situation. On the other hand, the

cumulative error of the series structure and the complexity of the

structure should also be considered. Usually the range for the number of

robot joints N is 2-10. The number of robot fish joints designed in

this paper is N = 6.

In the design of the length of each joint,

considering that the movement of the fish body is mainly concentrated in

the rear half of the fish body, therefore the first half 130 mm of the

fish can be viewed as not swinging. Also, according to the actual

measurement, it is known that the fish tail length is 47 mm. Based on

the joint size parameter optimization design method proposed by Chai

Zhikun [1],

except for the tail joint, the proportion of the remaining five joints

should be 83: 67: 59: 53: 48. The length of each joint after calculation

and rounding is: joint 1 is 22mm, joint 2 is 18mm, joint 3 is 16mm,

joint 4 is 14mm, joint 5 is 13mm, and the joint 6 (caudal fin) is 47mm

long.

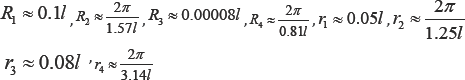

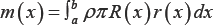

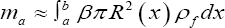

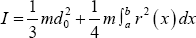

Calculation of the mass and moment of inertia of each part

Based on the above geometric parameters of the fish, the mass of the various parts of the fish can be calculated:

Where, ρ is the fish density (kg/m3),

which can be approximated as the density of water, a, b are the

abscissa values of the starting point and the end of each joint.

During the swimming process of the fish, due to

interaction with the surrounding fluid, the fish has a virtual mass.

According to Lighthill's "Large-amplitude elongated-body theory of fish

locomotion,” the equation for calculation of the virtual mass of the

fish body cross-section is [2]:

Where ρf is the fluid density, β is the virtual mass coefficient; when there is no fish fins on the fish cross-section,

β = 1.

As the robot fish cross-section can be regarded as an

oval with the long axis of 2R (x), the short axis of 2r (x), the

inertia of each part around the z-axis can be calculated according to

the following formula:

Where m is the sum of the mass of each joint and the

virtual mass, and do is the length of each joint. As this robot fish has

six joints, therefore there is seven parts in total. The following is

the calculated mass of each joint, virtual mass, and moment of inertia:

Kinematical Analysis of the Robot Fish

According to the observations of the tuna fish by Donley and Sepulveda and others [3], the fish body wave equation corresponding to the swimming locomotion of this type of fish is: h (x, t )= H (x) sin (ωt - kx) , where, h (x, t) is the lateral displacement of the fish. H (x) is the envelope equation of the fish’s swimming locomotion. ω is the swing frequency of each fish joint, k is the wave number of the fish body. k = 5.7/1 . H (x) = α1 + α2 + α3x2 , Where α1 = 0.02/ α2 =-0.12 α3 = 0.3/1.

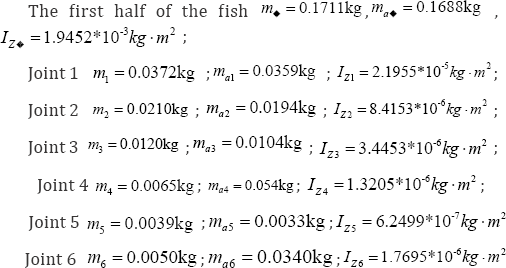

When the frequency of each joint is 2Hz, the swing

period is 0.5s. The swing cycle is divided into 10 moments. With the

starting point of each joint as the center, the joint length is the

intersection of the radius and the fish wave equation at that moment.

The coordinate position of the six joint starting points at each moment

was obtained (In this coordinate system, the front end of the fish head

is the coordinate origin, the forward direction of the swimming

direction is the negative direction of the x axis, and the direction of

the lateral displacement is the y direction, dynamic body coordinate

system). The following Table 1 is the calculated coordinates of each joint starting point at each moment.

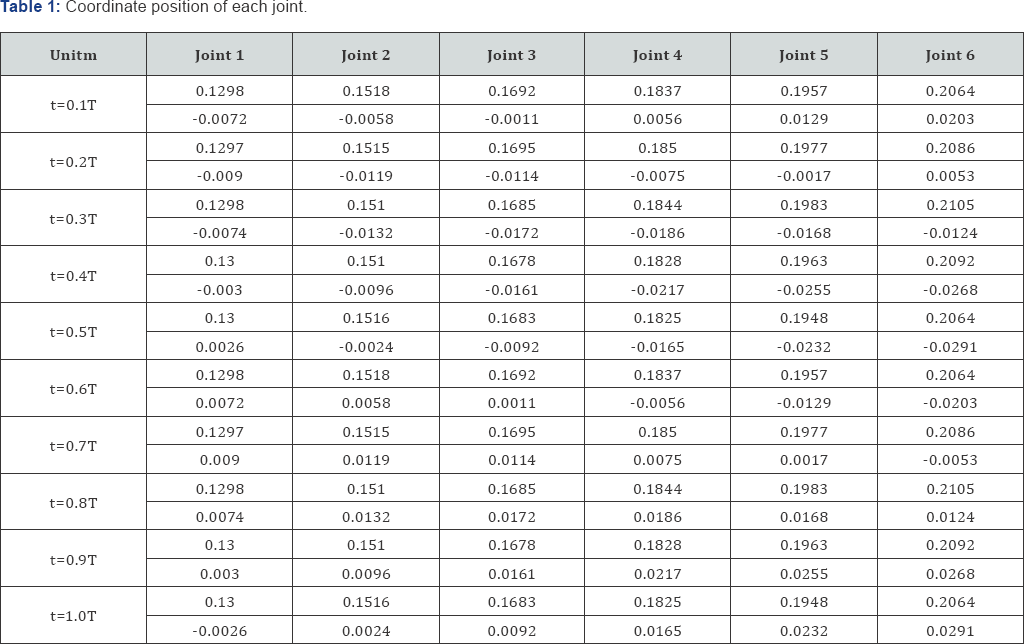

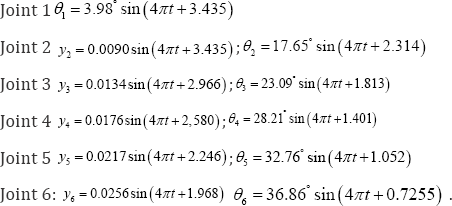

The swing movement law of each joint can be obtained by using curve fitting toolbox cftool of Matlab, As shown in Figure 1.

Fluent Flow Field Simulation and Kinetic Analysis of Robot Fish

The Cartesian coordinate system was established: the

negative direction of the x-axis was the advancing direction of the

fish, the z-axis was the transverse displacement direction of the fish,

and the y-axis was the longitudinal displacement direction of the fish.

Ignoring the force in the y-axis direction of the fish (gravity,

buoyancy, lift due to pectoral fins, and others), and considering only

the x-z plane force on the body during the advancing process, the fish

is only subjected to two forces: the resulting thrust due to swing water

and the resistance in the forward movement.

According to the "large-amplitude elongated-body

theory of fish locomotion,” the fish's thrust is the component of the

hydrodynamic force generated by the fish's swing in the forward

direction [4].

However, due to the complexity of the flow field, there is no standard

and uniform thrust formula. It is difficult to obtain relatively

accurate simulation results. Therefore, the fluent flow field analysis

method was used. The dynamic grid technology was used for the meshing of

the fluid around a certain area of the fish, and turbulence model was

used to obtain the solution. Hence, the forces exerted by the

surrounding fluid on the fish body during the steady state forward

movement can be obtained by simulation (surface pressure and viscous

force). Further, the thrust formula can be obtained.

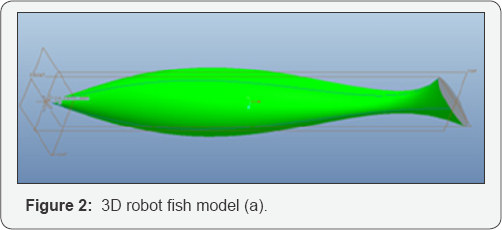

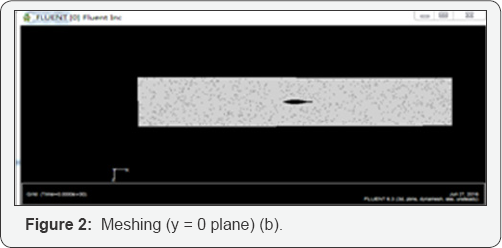

As shown in Figure 2a is a three-dimensional model of the extracted robot fish, Figure 2b

is a plane view intercepted at y = 0 after the static grid division is

completed. In the choice of computing domain, on the one hand, the

length of the calculation area must be large enough to meet the needs of

the continuous advance of the robot fish; on the other hand, the

smaller calculation area can improve the calculation efficiency. After

several trials, the calculation domain was selected as rectangular, the

length, width, and height were selected to be 10 times of the

corresponding maximum size of the biomimetic robot fish.

In the above model, the triangular/tetrahedral mesh

is used to divide the area/body domain of the region. Since the grid

boundary changes with time according to the variation trend of the fish

wave equation, it is necessary to define the grid as the dynamic grid in

the computing domain. Also, the spring smooth method and the local mesh

reconstruction method were used to ensure the quality of dynamic grid.

The following is the dynamic grid parameters: the spring coefficient is

0.2, the boundary node relaxation factor is 0.4, the maximum length of

the local reconstruction is 0.021, the minimum length is 0.0004, the

maximum cell skew rate is 0.76, and the size function is activated, and

the remaining values are default.

On the boundary condition, the boundary conditions of

the six surfaces of the rectangular parallelepiped and the surfaces of

the biomimetic robot fish are all non-slip condition on the wall

surface, but the dynamic region is defined by the UDF (User Defined

Functions) function. For the robot fish model, DEFINE-GRID-MOTION Macro

was used to define the movement of fish. Take the movement at the end of

the joint as an example; the custom program of this dynamic region can

be defined as follows:

#include "udf.h”

#define PI 3.1415926

DEFINE_GRID_MOTION (guanjie6,domain,dt,time,dtime)

{

Thread *tf = DT_THREAD(dt);

face_t f;

Node *v;

real NV_VEC(omega), NV_VEC(axis), NV_VEC(dx);

real NV_VEC(origin), NVVEC(rvec);

int n;

SET_DEFORMING_THREAD_FLAG(THREAD_T0(tf));

begin_f_loop(f,tf)

{

f_node_loop(f,tf,n)

{

v = F_NODE(f,tf,n);

if (NODE_POS_NEED_UPDATE (v))

{

NODE_POS_UPDATED(v);

NV_S(omega, =, 0.0);

NV_D(axis, =, 0.0, 1.0, 0.0);

origin[0] = 0.213;

origin[1] = NODE_Y(v);

origin[2] = 0;

omega[1] = 0.2587*PI*PI*sin(4*PI*time-0.3848+PI/2);

NV_VV(rvec, =, NODE_COORD(v), -, origin);

NV_CROSS(dx, omega, rvec);

NV_S(dx, *=, dtime);

NV_V(NODE_COORD(v), +=, dx);

}

}

}

end_f_loop(f,t)

}

In the choice of the calculation model, because the

robot fish movement belongs to the large Reynolds number movement mode,

therefore the transient three-dimensional turbulence model was used for

solution. Due to the wide range of applications (especially the

situation of high Reynolds number), economic, reasonable accuracy, and

other characteristics, k-epsilon turbulence model was used.

Since the surface of the fish is divided into seven

parts according to the joint position when drawing the three-dimensional

map, the force component of the wall area of the fish body in the

specified direction (the advancing direction of the robot fish) can be

obtained in the processing of the results.

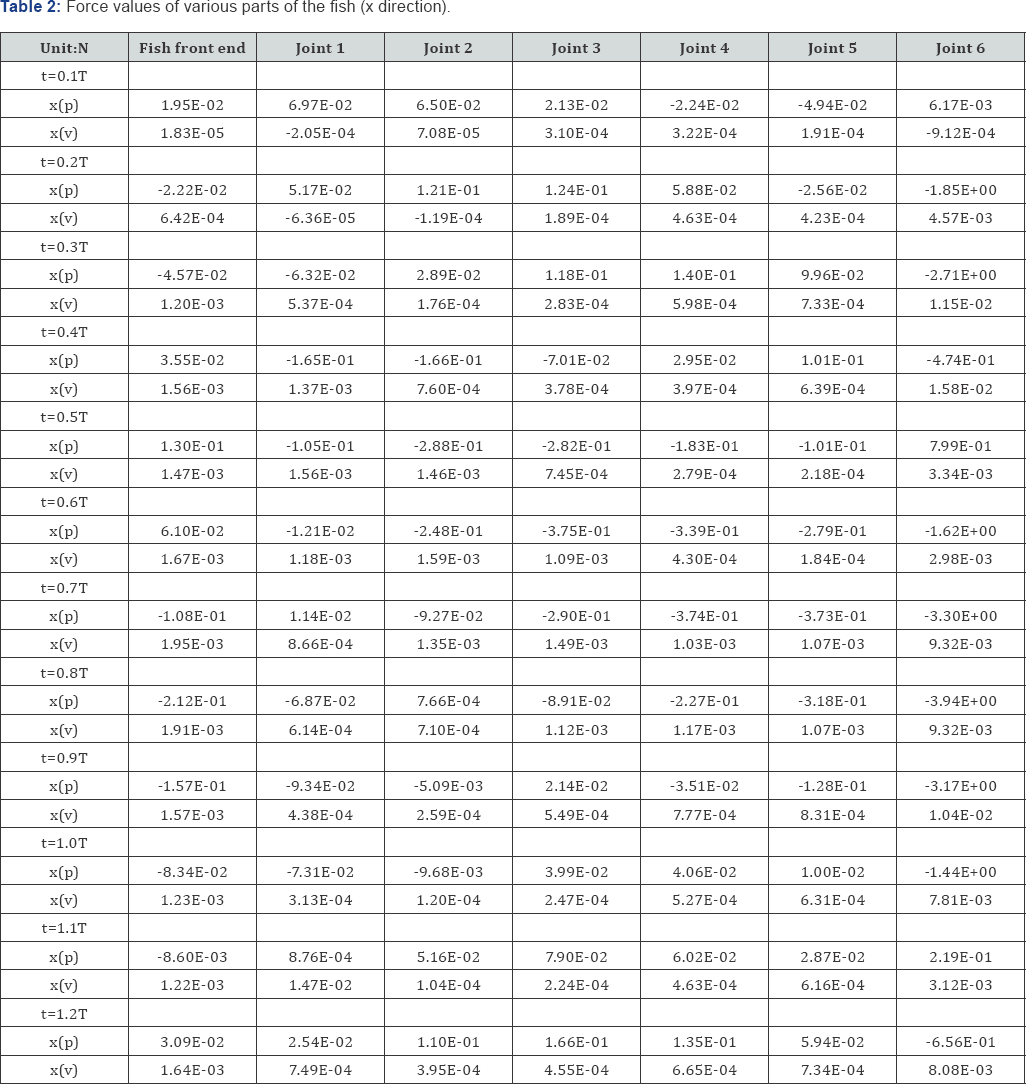

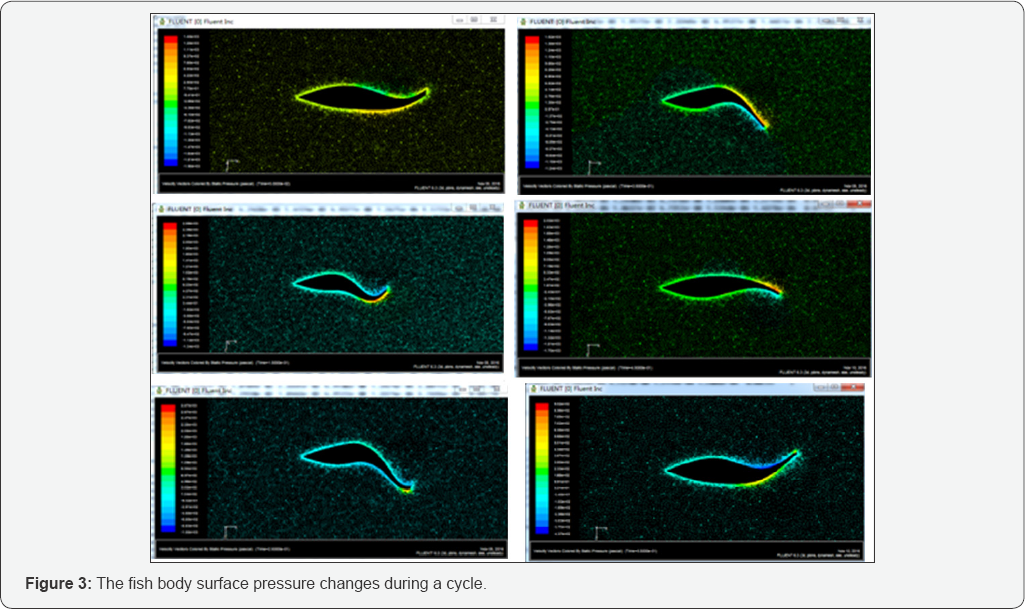

In Table 2, x(p) represents the fish surface pressure value, and x (v) represents the viscous force value. It can be seen from Figure 3 and Table 2

that the positive and negative surface pressure of the fish in the

z-direction is cancelled in one cycle, and the viscous force is usually

in the resistance state, and its value is small relative to the surface

pressure, the difference is 2-3 orders of magnitude. Consequently, it

can be neglected when fitting the thrust formula. The thrust value of

each part of the fish body can be obtained as follows (N):

Fish front end: T0 = 0.1094sin(4nt + 5.098)-0.0410 ;

Joint 1: T1 = 0.0875sin (8πt - 0.3221)-0.0477 ;

Joint 2: T2 = 0.1639sin(4πt + 0.9005)-0.0835 ;

Joint 3: T3 = 0.2328sin(4πt + 0.2085)-0.1045 ;

Joint 4: T4 = 0.2410sin(4πt-0.3612)-0.1170 ;

Joint 5: T5 = 0.2247sin(4πt + 5.575)-0.1360 ;

Joint 6: T6 = 1.638sin (8πt +1.881)-1.571 .

The influence of viscous resistance (frictional

resistance) is small and negligible in the case of fish swimming

locomotion that has a large Reynolds number (As demonstrated in Table 2). The pressure resistance, which played a major role, can be calculated by the standard Newton equation [5]:

Dp = 0.5CpSpU 2ρ

WhereCp is the resistance coefficient, usually 1.2; Sp is

the effective area, in the practical application ( is the displacement)

can be used as the effective area of action as the fish moves in the

water, because the density of fish and water are basically the same, Sp =(m/ρ)2/3 [6].U is the average speed of swimming locomotion; ρ is the density of water.

It can be concluded that the rear joint (caudal fin)

provides the maximum thrust, accounting for more than 80% of the total

thrust, so the caudal fin drive mode is selected; electromagnetic drive

has advantages of compact structure, pollution-free, high reliability,

and large driving force, and accurate process control can be achieved.

The cyclic oscillation-driving mode is selected to be the

electromagnetic drive.

Research on Control Signal of Electromagnetic Drive Robot Fish

Signal transformation

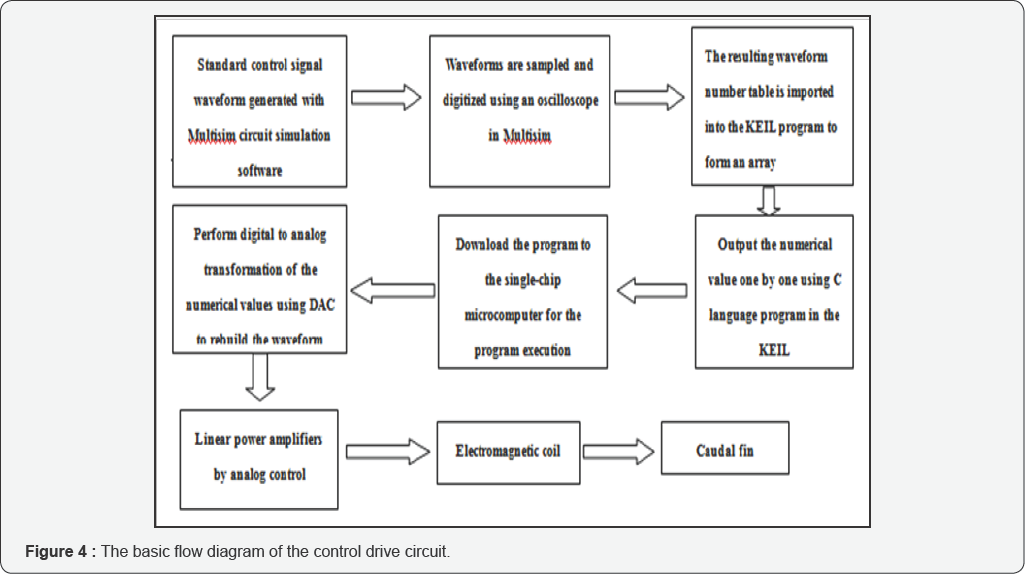

The standard electromagnetic coil current waveform

was digitized, and then through the MCU processing the signal was

transferred to the DAC module for digital-analog transformation to

reproduce the analog control signal. The realization of the control

signal was the acquisition, storage, and reproduction of the standard

control waveform, which was used to drive the electromagnetic coil that

further drove the caudal fin movement. The basic flow of the control

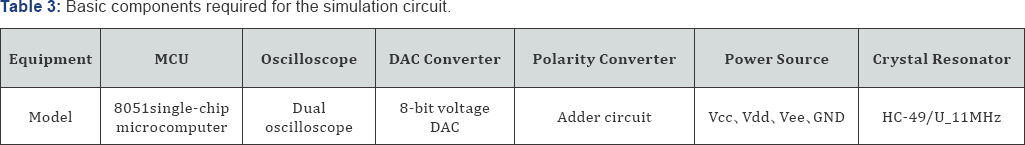

drive circuit is shown in Figure 4. The components used in the Multisim simulation are described in Table 3.

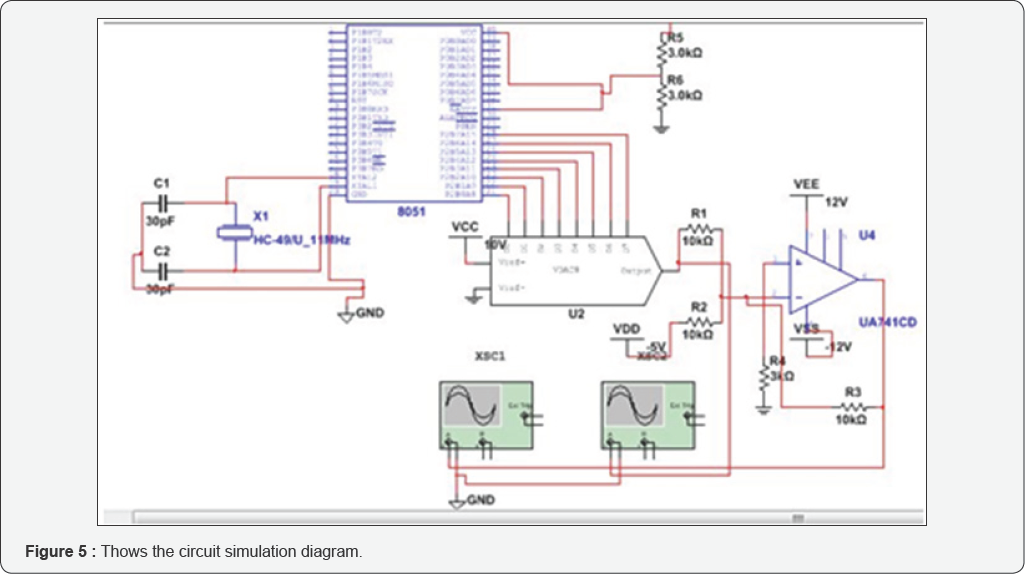

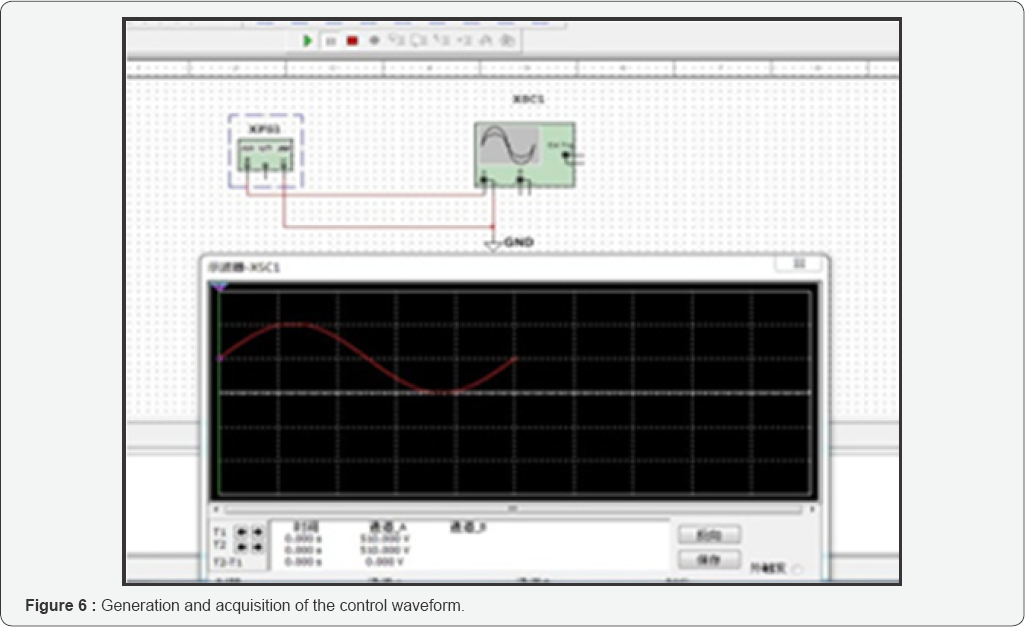

Simulation circuit has been completed. A waveform

generator and an oscilloscope were used as waveform generation and

acquisition circuit (sinusoidal wave as an example) in Multisim. The

amplitude was set to 255V, the cycle was 1s, as shown in Figure 4 & 5.

After the standard sine wave was obtained, the collection and digital discretization was required. As shown in Figure 6,

the oscilloscope in Multisim provided the function of waveform

sampling. Click "Save” on the oscilloscope in the figure, the settings

of the sampling time interval and number of sampling points of the

oscilloscope will be displayed. To ensure signal accuracy, 120 points

were sampled in a cycle. The sampled data was set as a binary output

text file.

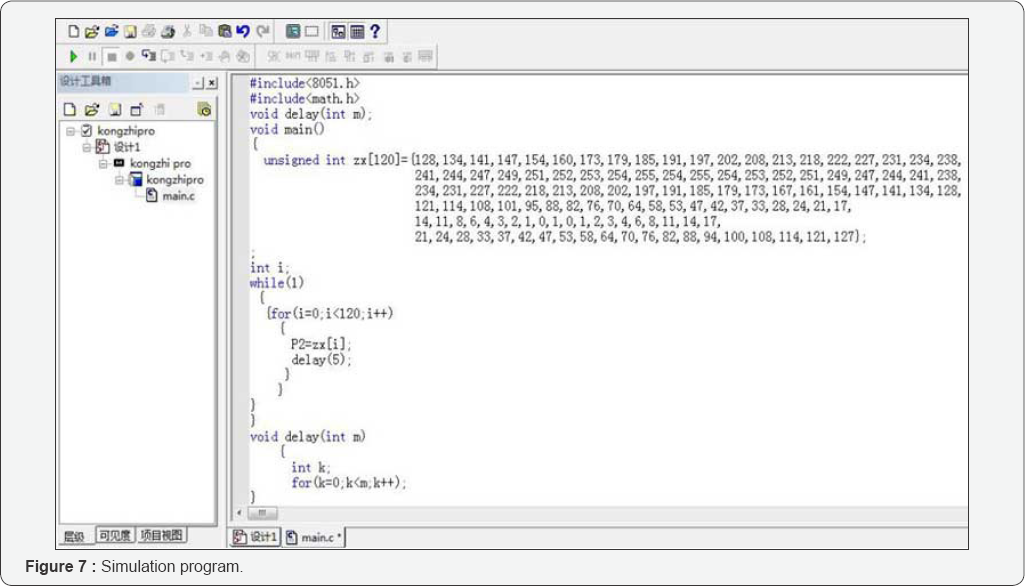

After the sampling data was obtained, start the

singlechip microcomputer-programming interface of the completed

circuit simulation platform. The collected discrete value's output was

through the single-chip microcomputer one by one cyclically. The

programming interface and the program are shown in Figure 7.

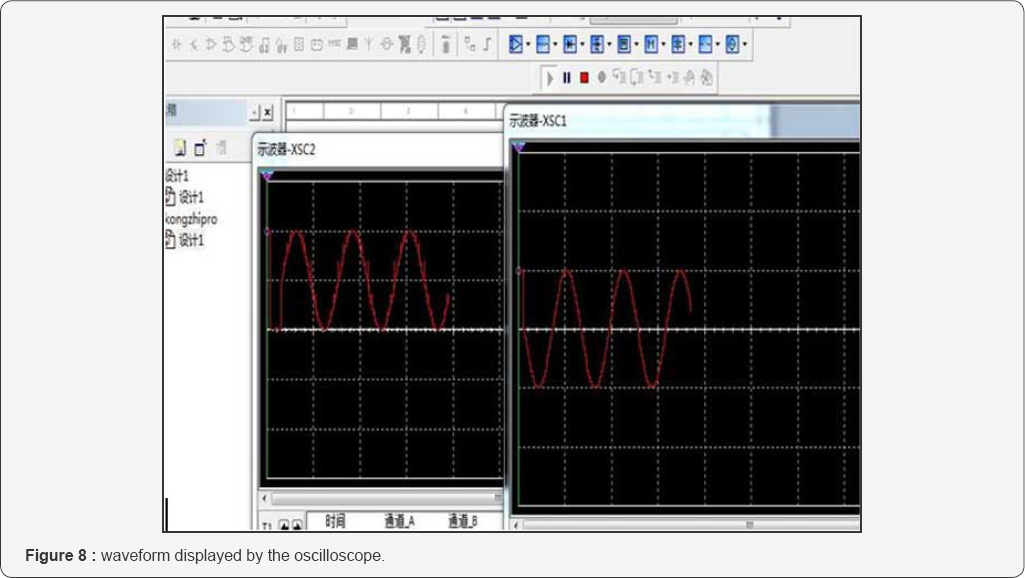

After programming, the program is successfully

downloaded to the single-chip microcomputer, click on the "start

simulation,” back to Figure 5 interface and open the two oscilloscopes in the figure, waveform as shown in Figure 8 can be observed (Figure 9).

Oscilloscope XSC2 displays the 8-bit DAC direct

output of the control signal; the oscilloscope XSC1 displays the output

control signal of the DAC output after passing through the polarity

converter. For the frequency of the waveform, delay value in the

parentheses of the delay statement in the program can be adjusted. When

calling the delay program, the singlechip microcomputer will adjust the

output hold time of each digit according to the delay value in

parentheses, and thus the frequency of the whole waveform can be

adjusted. The amplitude needs to be matched based on the characteristics

of the power amplifier module in the actual circuit and the DAC module

in the actual circuit has a reference voltage setting [7-10].

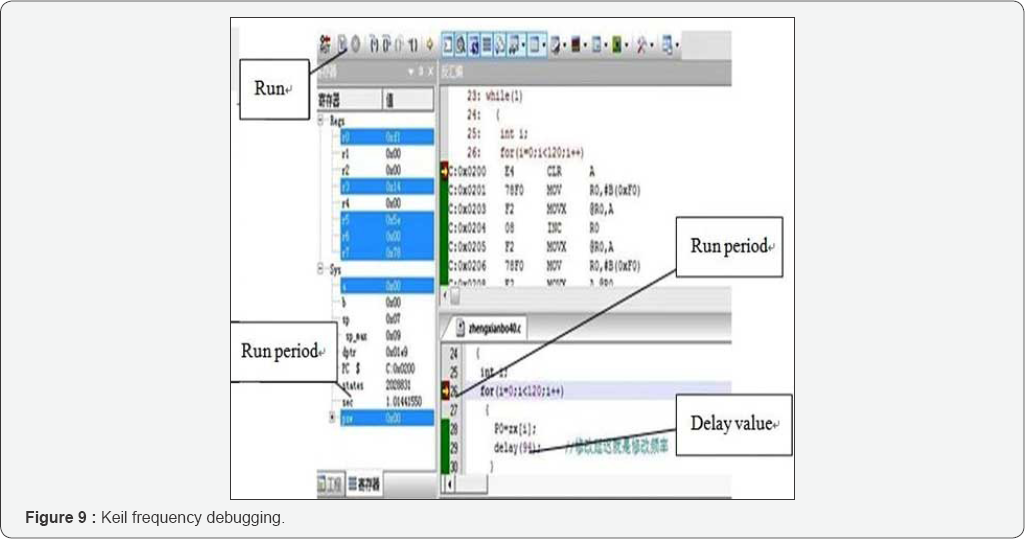

The simulation program as shown in Figure 3 & 4

was then transplanted to the Keil single-chip microcomputer programming

software. After the program was successfully compiled, the crystal

resonator frequency was set to be the crystal resonating frequency of

the single-chip microcomputer, which was 12Mhz. The Keil debugging

interface was started, break points out of the cycles were set, and the

delay parameter in the brackets of the "delay ()” statement was adjusted

continuously until the output cycle reached 1s, namely, control signal

so that the caudal fin swing cycle was 1Hz. The debugging interface of

Keil as shown in Figure 4 & 5

was entered. In every click of "run”, the program executed a cycle, and

"sec” increased accordingly, and the added value was the time required

to output a complete waveform [11-14].

After debugging, the program was downloaded to the

single-chip microcomputer. The DAC output control waveform can be

observed by connecting the DAC module output with the oscilloscope. It

can be seen that the actual circuit output control signal and the

simulation circuit output signal were exactly the same.

Signal adjustment

The DAC module was connected with the STC89C52

development board with the downloaded test program. The output of the

DAC module was connected to the input of the power amplifier module. The

DAC module and the power amplifier module shared the DC ± 15V power

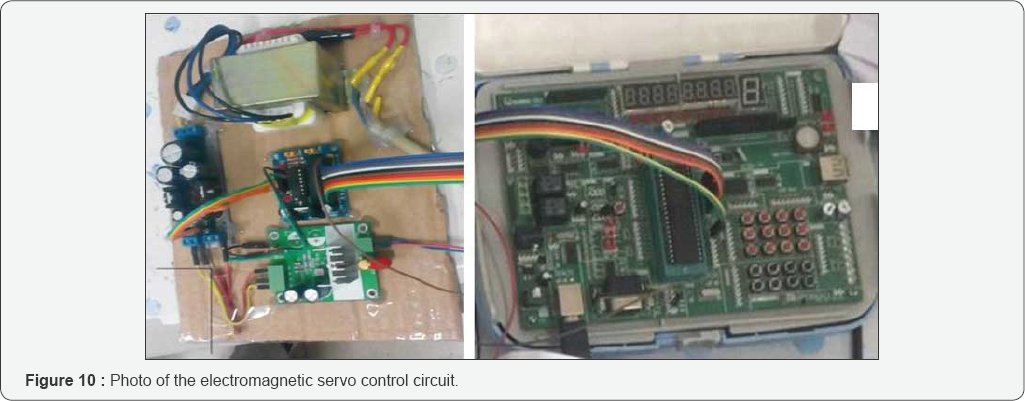

supply. The overall circuit of the control platform is shown in Figure 10.

The "delay ()” delay parameter was modified in the Keil programming

debugging interface, the signal frequency was the electromagnetic coil

operating frequency.

Experimental Study

Development of experimental prototype of robot fish

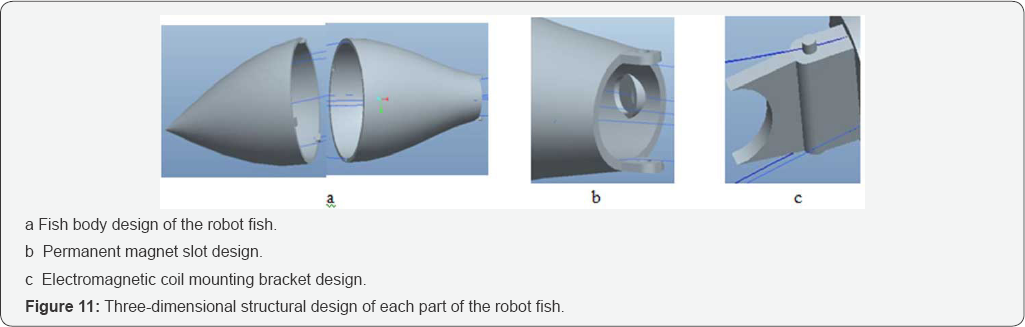

The external fish body shape curve was imported into

the Pro/E three-dimensional modelling software; closed fish surface

shape can be obtained by the use of "variable crosssection scanning”

tool. Then, "thickening” operation was performed on the surface, with

the set thickness of 1.8 mm. The closed fish body shell was thus

obtained. Considering the fish body assembly, weight allocation, fish

body was designed into a removable form, as shown in Figure 11.

After modeling, the fish body model was obtained with

the use of precision 3D printing, the printing material was resin. The

polypropylene caudal fins were tailored to thin caudal fins according to

the caudal fins of the actual tuna fish, and the flexible caudal fins

were then fixed on the connecting parts as shown in Figure 12. Underwater experiments are shown in

Figure 13.

Electromagnetic drive robot fish underwater experiment

Fish body linear curve swimming experiment: In

the

experiment, the swing frequency of the fish when swimming along straight

lines is set within 1-8Hz. The amplitude of the drive voltage is set

between 2-6V. After adjustment of the fish weight, the control signal

waveform acquisition was used to generate 1-8Hz sinusoidal signal, the

signal waveform are shown in Figure 14.

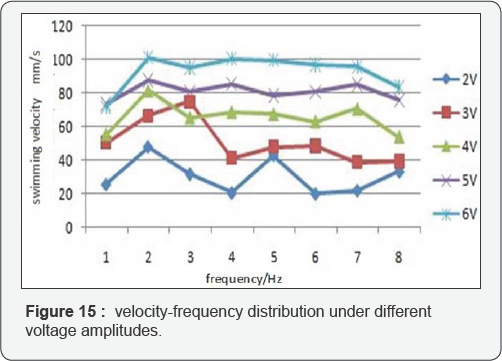

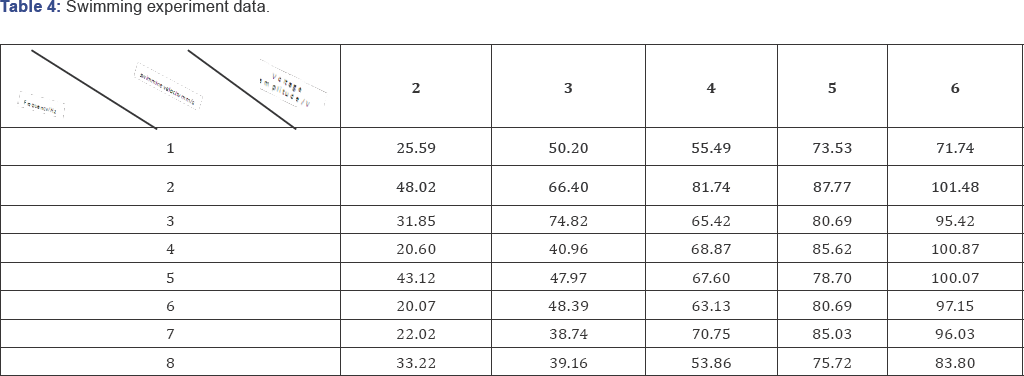

By adjusting the frequency of the control signal through adjusting the

delay time of the sinusoidal output program, the obtained experimental

data is recorded in Table 4, the distribution diagram of velocity - frequency under different voltage amplitude is shown in Figure 15.

The above data is shown in Figure 15.

The greater the amplitude of the driving voltage signal, the faster the

fish swims. At different drive voltage amplitude, the best swing

frequency was basically the same; at about 2Hz, the fastest swimming

speed was achieved. As the high drive voltage heats up the coil, it is

desirable to operate at low voltage, hence at 2 V voltage, 2Hz, the

swimming speed of 81.74mm/s was selected as the best electromagnetic

drive control signal [15-18].

Conclusion

Based on the actual physical appearance of the tuna

and the wave equation derived from observing its swimming locomotion,

the motion law of each joint of the robot fish is obtained through the

discrete fitting method, and the motion law is utilized as the basis of

the control signal of the electromagnetically driven robot fish. With

the utilization of the fluent flow field analysis software, a dynamic

grid technique was used to mesh the fluid around the fish body. By

analyzing the surface pressure value of the simulated fish body in the

steady state of forward movement, the thrust values of each part of the

fish body were obtained. Hence, the electromagnetic-driven caudal fin

robot fish was determined as the optimal design. Based on the idea of

digital-analog conversion, the drive control signal waveform was first

digitally discretized. Then, it was converted through the C51

single-chip microcomputer and DAC digital-to-analog converter. Finally,

the simulated amplified analog output was obtained through the OPA544 op

amp chip in accordance with the waveform of the control signal.

Electromagnetic coil drive signal with variable frequency and voltage

was thus achieved. An electromagnetic driven caudal fin robot fish

prototype was successfully produced, a number of robot fish underwater

experiments were designed, and a series of experimental data was

obtained. Based on the linear swimming experiment of the robot fish

prototype, it was obtained that the optimal value of the electromagnetic

drive signal is 2V, 2HZ when the electromagnetic driven caudal fin

robot fish was at a relatively high speed. Based on this, the next steps

of the study lays on the following two aspects:

For more open access journals please visit: Juniper publishers

For more articles please click on: Robotics & Automation Engineering Journal

Comments

Post a Comment