Collaborative Robots in a Human-Centered Assembly System- Juniper Publishers

Juniper Publishers- Journal of Robotics

Abstract

This paper offers a brief overview of collaborative

robots and the importance of Design for automated assembly. This means

to not only design the assembly stations with user friendly cobots but

also to analyze and improve the product towards higher physical level of

automation in assembly systems.

Keywords: Collaborative robots; Design for Automated Assembly; Assembly systems; Human-centered

Introduction

Human-centered assembly systems can be describe as a system designed to interact with people intelligently [1].

Collaborative robots is getting more and more common as a solution to

increase the level of automation in production and assembly systems [2]. Case-studies conducted in Sweden shows that over 90 percent of assembly systems still are manual [3],

the cobots could be a solution in order to decrease this percent and to

get more cobots into assembly stations. In cases where the robots are

installed it is more co-existing than collaborative, but there are some

solutions towards a collaborative environment [4-6].

In order to get truly collaborative workstations, the robot and the

operator needs to share both the station and the work piece according to

the standard ISO/TS 15066:2016. Today a lot of the solutions are

technology driven towards cyber physical systems and different virtual

tolls, such as augmented reality. Hence, in order to achieve

collaborative work stations, well designed products for automation is

vital in order to create a well functional collaborative work station.

Design for Automated Assembly (DFAA)

An important step towards an increased level of

physical automation is to design the products for automated stations.

One method is DFA(A), this method was first published over twenty years

ago The idea is to reduce the manufacturing cost such that the design

eases manufacture of the parts making up the complete product without

compromising quality of the final product [7]. Even though, product cost savings between 15% and 70% have resulted from analysis and redesign [8]

using DFA-analysis not many companies uses this method in Sweden. DFAA

provides a clear picture of which components and tasks should be

prioritized to increase automation and could be divided into two main

levels, product level and component level [9]. An industrial case study performed in final assembly aimed to increase automation [6]

also showed a possible improvement of almost 70 percent on the product

level, using DFAA-analysis. The main improvement was to decide a

component to be a main base object and to design fixtures. Fixtures are

very important in order to increase automation in a system [10] and flexible fixturing [11]

can enable an adaptable fixture to be used in a mass customized

systems, which the assembly system often is. The fixtures should be

designed for the main product but also for the components, in order to

be kitted and easily handled by the cobot. On a component level, the

main improvement was also fixturing and sorting of components. A

time-saving of 68 percent per product i.e. 266.8sec ~ 4.5min/product. If

the company produces 10000 products/year = 750h = 18 weeks = 600 000

SEK (if the salary for the operator is 800sek/h). The automated station

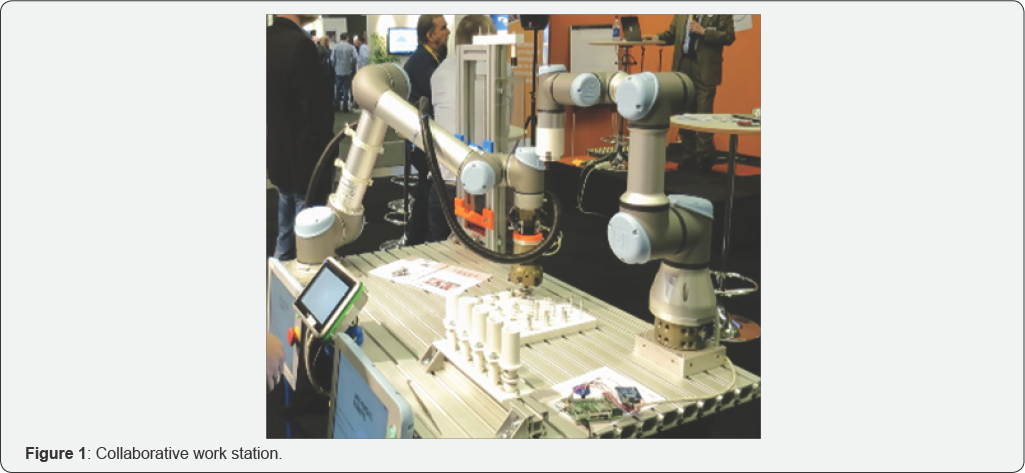

illustrated in Figure 1 costs around 500 000 SEK, which means that RoI of this stations is less than 18 weeks.

The assembly fixtures and component fixtures were 3D

printed as a first step. The operator and the robot is sharing the

component fixture, but it is also possible to share the assembly fixture

as well. This means that the station can be defined as a truly

collaborative work station.

Conclusion

In order to increase the usage of cobots in a human-

centered assembly system, the usage of a method such as DFAA needs to be

further developed in order to increase automation in final assembly.

When the allocation between humans and automation is decided,

collaborative work stations can be designed. This paper has presented

some thoughts about the need for a standardization and product design

for automated assembly systems. Cobots is one solution towards an

increase of levels of automation in assembly systems but the product

design might be as important as the safety and user-friendly and

collaborative robots.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Robotics & Automation Engineering Journal

Comments

Post a Comment