Design of a Cyber Physical Industrial Robotic Manipulator- Juniper Publishers

Juniper Publishers- Journal of Robotics

Abstract

A key component of Cyber Physical Production Systems

(CPPS) are connected Cyber Physical Machines (CPMs), or smart machines,

which can act independently to each other and communicate in situation

dependant ways. This new era of connected manufacturing has brought

about new requirements for machines which are being deployed to the

manufacturing shop floor. Cyber physical machines are not only required

to execute industrial or manufacturing process, but they need to be

capable of meeting other requirements, such as self-diagnoses,

intelligent decision making, modularity and networkability. This

research explores the design process of cyber physical machines as it is

applied to the design of an industrial robotic manipulator.

Keywords: Industry 4.0; Design Process; Manufacturing

Abbreviations : CPPS:

Cyber Physical Production Systems; CPM: Cyber Physical Machines; IoT:

Internet of Things; CPS: Cyber Physical Systems; FDM: Fused Deposition

Modelling, SLA: Stereo lithography; DP: Design Parameters; FR:

Functional Requirements; COTS: Commercially Off The Shelf

Introduction

Cyber physical production systems

The “Internet of Things (IoT)” and “Cyber Physical Systems (CPS)” [1]

are bringing about a digital transformation to the traditional shop

floor. The full industrial implementation of Cyber Physical Production

Systems(CPPS) in manufacturing environments is bringing about the fourth

industrial revolution or as defined by the German Federal Minister of

Education and Research, Industry 4.0 [2].

Cyber Physical Production Systems (CPPS) consist of

autonomous and cooperative elements (e.g. Cyber Physical Machines) and

systems (e.g. Smart Factories) that are connected with each other in

situation dependent ways, on and across all levels of production, from

the processes level up to factory and production levels [3].

This new reality is being brought about by advances in technologies

such as low power electronics, wireless communications, smart sensors [4], cloud manufacturing [5], advanced communication protocols such as OPC/UA [6] and data models such as Automation ML [7].

Cyber physical machines

As previously stated CPPS are composed of smart

machines which are networked to each other.Smart machines, or cyber

physical machines, are at the core of Industry 4.0. They are embedded

with new capabilities and enabling technologies. This makes it possible

to achieve functions which were not previously possible. For example,

sensors on board of a cyber physical machine can be monitored remotely

in real-time. This allows an intelligent Condition Monitoring System

(CMS) to diagnose the machines condition and make it possible to carry

out routine maintenance before a breakdown in the machine, possibly

avoiding costly downtime [8].

The need for continuous adaptation has also driven

the development of approaches that implement the concept of plug-

and-produce. Plug-and-produce allows for different elements of a

production system to be added and removed from the production system

depending on the needs of production. This concept of plug-and-produce

also allows for the development of modular production systems. As

explained by several authors, Schleipen et al. [9], Onori [10] and Maeda [11],

the concept of plug-and-produce must be supported not only from a

mechanical function, but also by the development of new and improved

software and control paradigms.

Therefore another characteristic which is central to

CPPS is decentralized and cognitive control. This is achieved by using

machines that have embedded processing and networking capabilities [12].

This distributed control is gaining further popularity with the

capability to use cognitive processing to analyze data gathered from

machine sensors which allows for the decentralization of the CPPS

control.

Collaborative and connected robotics

.The emergence of CPPSs has also brought with it an

increased utilization of robotics. This trend has been highlighted at

the World Economic Forum in Davos, which identifies advanced robotics as

one of the main technological drivers behind Industry 4.0. Industrial

robotics provides high efficiency and precision whilst being flexible

and re- deployable. Robots have seen increased utilization where fast

cycle times of repetitive tasks needs to be maintained.

That said, this does not mean that humans will be

completely eradicated from the shop floor. In fact based on detailed

studies and experimentation conducted, Pfeiffer [13]

argues that human experience will be still needed on the future shop

floor. Based on this, the need for humans and robots to collaborate

together on manufacturing operations will increase in the coming years [14].

In response to this growing need, it can in fact be seen how all major

robot manufacturers are introducing to their lineup collaborative robots

who are capable of working hand-in-hand with human operators.

Collaborative robots are industrial robots which have been designed to

confirm with specific safety standards which allow them to work within

close proximity to human operators.

Research aims

Cyber physical machines need to be developed with

specific characteristics as described above, in order to be implemented

into CPPSs. These include characteristics such as communication,

intelligence, modularity, which would allow these robots to communicate

with the manufacturing cloud. The first activity in designing cyber

physical machines is to define the requirements that need to be met and

the functions which need to be executed. A solution is then synthesised

from a set of design elements in order to meet these requirements. As

will be presented in Section 2 from a review of the state of the art

there are very few approaches which tackle the design approach of cyber

physical machines.In order to understand the design process of cyber

physical machines this research aims to explore the design process of a

cyber physical industrial robotic manipulator.Section 3therefore

describes the design process utilized to develop the industrial robotic

manipulator, and the knowledge which was gained from this exercise.

Section 4 then presents the prototype design and implementation. The

conclusions and future work relating to this research are presented in

Section 5.

State of the Art

In this section the authors present the state of the

art relating to the topics of this research. Networked robots are

defined as a system of multiple robots communicating with each other

over a network, thus coordinating various tasks and roles, sometimes

even with human operators. This means that networked robots are

classified into two classes: teleoperated and autonomous. Teleoperated

robots are controlled by humans, who send commands and receive feedback

over the network. Autonomous robots communicate together as mentioned

earlier, without the necessity of human intervention [15].

For autonomous robotic networks, it is ideal to have a decentralised

network, thus allowing for a set of industrial robots to work together

over a network. This promotes fast and optimum communication between

these robots [15,16] without the need of other robot systems to receive the information from a centralised controller.

Democratization of technology refers to the process

by which more people rapidly gain access to technology. An approach to

meet this need is to facilitate the implementation of robotics by

developing cheaper and more customizable robots that can be easily

implemented by small to medium enterprises. Rapid prototyping technology

is thereforeoften used to develop open-source 3D printable dextrous

anthropomorphic robots. By using rapid prototyping, the designers were

able to create the design at a low cost. Moreover, the hardware and

software designs were made available online, thus encouraging further

improvement of the concept by the engineering community. This introduces

an activity known as the democratisation of robotics, which means that

the design of this robot system had to be accessible and usable by

anyone [17,18].

Onal et al. have similarly succeeded in using rapid prototyping to

provide a quick and inexpensive method to produce robotic manipulators [19]

. In the case of Onal et al., 3D printing methods were used to create

robot designs based on the structure of origami. Although this design is

not currently used in any industrial applications, it proves the

possibility of using RP to reduce costs while maintaining quality and

increasing production speed [18,19].

We can note that several enterprises are founded on the basis of rapid

prototyping robotic manipulators such as Franka Emika, which has created

its own RP robotic manipulator. This has seven degrees of freedom, and

is also able to communicate using Ethernet (TCP/IP) network standards.

This manipulator also incorporates several safety features, such as

collision detection, force sensing and virtual wall collision avoidance [20] .

During this research several design methods for CPPS and CPS were also reviewed [21-23].

Whilst they all highlight the multiple perspectives of CPPS, none of

these illustrates the design process from requirements to the final

design. This lack of CPPS design methods has also been highlighted by

Fisher et al. [23].

From the literature review carried out the authors

can conclude that there is no approach which combines 3D printed robots

designed using a generative design approach for use in CPPS. As argued

in Section 1, such an approach would decrease implementation costs and

therefore sustain the democratization of robotics hence supporting SMEs

in implementing CPPS.

Cyber Physical Machine Design Process

The design process must describe the design

activities from goal (the requirements) to means (the approved design).

To meet the aims of cyber physical production, a design process for

Cyber Physical Machines (CPM) needs to be utilized that that takes into

consideration not only the Physical but also the Cyber perspectives.

This research utilized the systematic design process depicted by

Roozenburg's basic design cycle [24]

as a basis to explore the activities involved in designing CPMs. The

different activities involved in designing CPMs being proposed by this

approach will therefore be described in the next section.

Analysis of CPM functional requirements

The first activity carried out in design is an

Analysis of the requirements that need to be met. When starting a new

design cycle the designer begins by analyzing the requirements for the

CPM. During the analysis the designer forms a better understanding of

the problems (problem statement) and determines the goals that need to

be achieved.

The basic goal of a CPM is to carry out the required

manufacturing process at the required time, cost and quality and

flexibility [25].

The analysis of the CPM requirements will also define the criteria by

which the manufacturing system solution will be evaluated in future

design activities. As described in the introduction, beyond these basic

requirements, there are several other requirements which need to be met

by CPMs. Therefore, if a CPM needs to operate within a CPPS the CPM

requirements must include the capabilities of configurability,

modularity, diagnosability and connectability. If the CPM solution does

not meet these requirements it cannot be considered as a cyber physical

system.

CPM synthesis

The next activity in the design cycle is Synthesis.

Synthesis can be defined as the combination of components or elements to

form a connected whole. It is in this activity of the design process

that the CPM designer develops solutions for the design problems.

Blessing [26]

states that the synthesis activity can be broken down into some

sub-activities. For example the 'generate' activity creates or finds

elements suitable for the solution which are then 'selected' and

'synthesised' into possible solutions. It is also important to note that

designers make selection commitments based on the CPM requirements

defined in the previous activity.

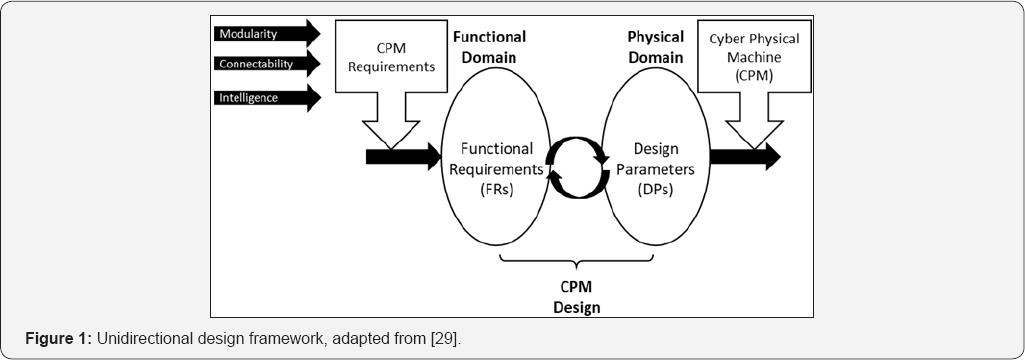

Based on the principles of axiomatic design [27], and as illustrated in Figure 1, Chryssolouris [25] and ElMaraghy [28]

discuss that design synthesis is the activity of mapping from the

functional requirements (FRs) onto suitable values of design parameters

(DPs).

These decision variables combine to make a system,

which describes both the physical design (Compositional View) and the

manner of operation of the CPM (Functional View) [29].

This research proposes that during synthesis of CPM,

consciously or not, designers make commitment in the cyber and physical

domains. This research is therefore prescribing a synthesis design

approach were designers take provisional commitments in these two

domains. The result of the synthesis from the different domains of CPM

design is a provisional design solution.

Simulation: The next stage of the CPM design

cycle involves the Simulation of the provisional CPM design solution.

Simulation involves the generation of an artificial history of a system

and the observation of that history to draw inferences concerning the

operating characteristics of the real system. The result of this study

is the expected properties of the provisional CPM design solution. As

explained by Hehenberger et al. [30],

in order to simulate the full capabilities of a CPM, tools are required

which model and simulate not only the physical performance of the CPM,

but also the information and communications exchange between systems.

Evaluation: During Evaluation of the

provisional design solution the expected properties are compared to the

design criteria established during the analysis stage. A value is then

given to that design solution to quantify how well the provisional

solution meets the CPM requirements.

Decision: The manufacturing system designer

will then Decide whether to continue developing the design by further

elaborating the provisional design or whether to try a different type of

solution to generate a better design proposal. Once the manufacturing

system designer is satisfied that the provisional design meets the

requirements and criteria then the status will be upgraded to that of

final design and the project can move on to implementation planning.

Prototype Design and Implementation

The CPM design process previously discussed was used

during this research in order to design and implement the cyber

connected industrial robotic manipulator which is discussed in this

section.

Physical Component Design

The physical component design process results in the

physical interface of the robotic manipulator. The physical system

design utilizes a set of robotic joint modules, some of which are

connected by a link module. Once produced and assembled, the robotic

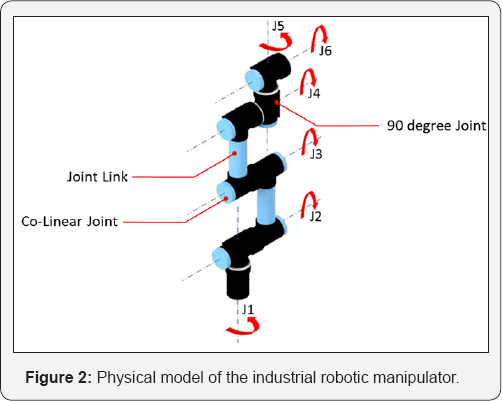

manipulator is essentially an articulated robot as shown in Figure 2. The manipulator is driven with the use of stepper motors in the joint modules.

Design for modularity: In order to meet the

requirements of being customizable for different industrial

applications, the physical robotic manipulator design is configured by

selecting, adding and removing joint and link modules. This design

configuration was chosen specifically as it allows for the design of a

modular industrial robotic manipulator, with the addition or subtraction

of joints and motors depending on the application required. The design

for modularity approach adopted here means that modules and interfaces

between modules needed to be designed. The main module of this robotic

manipulator is the joint which contains the servo motor. Two different

configurations of this module were developed; the co-linear axis of

rotation module, and the 90-degree axis of rotation module. The other

module which was designed was the joint link module which connects the

joints to each other.

The main configuration of the robotic manipulator is the one illustrated in Figure 2,

and which employs six degrees of freedom. This means that the robotic

manipulator is made up of six joints, each of which is a revolute joint.

The six degrees of freedom ensure that the end effectors can reach any

position and orientation within the workspace of the manipulator.

Different stepper motor sizes and gear ratios are used in order to lift a

1.5kg load at maximum extension.

Design for 3D printing: Since this robotic

manipulator was intended to be mostly rapid prototyped, several factors

and constraints needed to be taken into account during production of the

prototype. Fused Deposition Modelling (FDM) and Stereo lithography

(SLA) were used as the processes of rapid prototyping. The process was

chosen based on the geometry of each part. Parts which had important

geometry on one of their sides were 3D printed using SLA, such as the

specially designed gears. Placing the side with the important geometry

away from the support material was important for the preservation of

said geometry.

On the other hand, parts which have a flat surface on

one of their sides were printed using FDM, with that side being placed

on the printing bed. The use of FDM was also encouraged when 3D printed

parts required support material in internal and unreachable parts.

Soluble support was used in these cases, making the support material

easily removable during postprocessing.

In designing for 3D printing, an important factor

considered was the minimization of weight. While modeling using CAD,

several parts were designed to have the minimum wall thickness possible.

This first step led to the search for other possible means of weight

reduction. This included reduction in the diameter of the joints modules

which led to all the internal parts also being smaller, and thus

lighter.

Cyber component design

Requirements: The design goal for the control

system of this device is for it to encourage integration with other

systems and to encourage further development by system integrators.

Integration must be done in a simple and rapid manner, on both the

hardware and software domains. The system must be based on standardized

or open source software control and development tools. To maintain a

democratic design, the control hardware must be based on commercially

off the shelf parts (COTS), enabling a low cost solution.

Industrial Ethernet: An industrial network

based on Ethernet hardware shall serve as the backbone of the control

system. There are multiple relevant industrial Ethernet protocols; the

one selected for this solution is Ether CAT.

Ether CAT is an industrial network based on the

standard Ethernet physical layer (Ethernet PHY). The network is

deterministic, and can be used in a real-time environment. It supports

shorter cycle times than other industrial networks, which make it

suitable for motion control applications. Apart from the suitable

performance Ether CAT provides, there are other factors which make it

suitable for a system intended for the democratization of robotic

technologies.

When networks are based on the Ethernet PHY, they

would typically require a managed network switch, every Ether CAT device

has two Ethernet PHYs which enable them to be connected via a daisy

chain configuration, eliminating the need for a network switch if a ring

network topology suffices. Furthermore, Ether CAT slave devices are

responsible for controlling the timing of the network, without the need

for a specialized master network controller. Therefore, the master

device in an Ether CAT network can use common COTS Ethernet network

interface cards (NIC), keeping the cost of implementing an Ether CAT

network even lower. The use of a standard NIC allows for the

implementation of an Ether CAT master through the use of any suitable

device with basic Ethernet capabilities, this includes using a Raspberry

Pi should the developer see fit.

Ether CAT is an open source technology, encouraging the development of hardware and software to work with this technology.

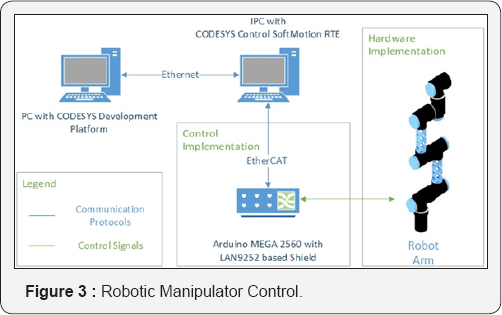

Robot controller: As illustrated in Figure 3,

the robot controller was based on the ATMega2560, developed through

Arduino/Genuino development platforms. Apart from the low cost required

for developing solutions with Arduino, the vast user base contributing

to various projects shortens and simplifies the microcontroller

development cycle.

As illustrated in Figure 3,

the microcontroller was interfaced to the Ether CAT network via

Microchip's LAN9252 Ether CAT controller for slave devices using SPI

communication. A COTS add-on (shield) to the Arduino platform based on

the LAN9252 is produced by AB&T Srl. The robot controller receives

the joint positional data from its Ether CAT master and subsequently

translates from joint position to the required pulses to drive the

stepper motor.

Master controller: To support the flexibility

required in the control system to adapt to different robot kinematic

parameters, a real-time soft PLC was used. The soft PLC implemented was

CODESYS Control Soft Motion RTE, it is developed using the 1EC 61131-3

compliant CODESYS V3.5 development environment. The CODESYS development

environment is free of charge, it also includes non-real-time versions

of the soft PLC systems.

Once again, the low cost of the system enables the

democratization of the control software and hardware. As of the time of

writing, the real-time versions of the soft PLC systems can be

downloaded and used without a license for a limited time before

requiring a restart. CODESYS Soft Motion also has the inbuilt

functionality to derive robot kinematics by defining the robot's

Denavit-Hartenberg parameters (DH parameters).

Conclusion

This research therefore explored the design process

of Cyber Physical Machines, through the application of this process to

an industrial robotic manipulator. This approach considers not only the

physical and hardware development but also the cyber and connectivity

perspectives of CPMs. Future work by this research initiative will

explore in further detail the cyber and physical elements of CPMs. The

aim is to develop a knowledge based design support tool which can guide

and support designers in taking decisions during the CPM design process.

Acknowledgement

The authors acknowledge the University of Malta for

the financial support through the Research Grant "Digital Planning and

Simulation for the Factory of the Future” (Vote No. 1MERP 05-16).

For more open access journals please visit: Juniper publishers

For more articles please click on: Robotics & Automation Engineering Journal

Comments

Post a Comment