Study of Stress on Belt Drive System Integrated with Briquetting Plant- Juniper Publishers

Juniper Publishers- Journal of Robotics

Abstract

In briquetting plant, briquettes produces through

small pieces of agro residues or by dry material which having moisture

contain below 10%. Briquetting plant consists from biomass grinder,

screw conveyor and piston-press machine. The piston-press machine

operates through open belt drive system. Pulley and belt system is an

important part of the briquetting plant, which function is to transfer

speed into reciprocating system. In this study, effect of slip and COF

on belt life analysis has done through mathematical formulation and

numerical simulation. Present study deals pulley simulation has done

through help of Finite Element software ANSYS 12.0.1.

Keywords: ANSYS; Briquetting plant; COF; Pulley-belt; Slip

Introduction

We all are well known by the importance of energy and

its sources. Energy is the key factor in economic development of every

country. The demand of energy is increasing day by day and the supplies

of sources are limited. It is globally red alert for fossil fuel like

Petrol, Kerosene, Natural Gas, LPG, and Lignite etc. This has made a

huge gap between the demand and supply of energy. Renewable energy is

the ultimate solution, which can fill this gap.

The briquette is an alternate source of energy. The

biomass briquettes are substitute for coal and L.P.G., and research is

going on. The Biomass briquettes are made up of renewable source of

energy.

The briquetting piston-press is a reciprocating

crank type mechanical press with flywheel. The main motor through

continuous flat belt drives flywheel. The ground material is feed

through a hopper by means of a screw conveyer with its own motor. The

vertical screw pre compresses and forces the material downward in to the

feeding chamber. From the chamber the materials forced by the ram

through a tapered die system on to the cooling track in the form of

briquettes. Briquettes formed are cylinder shape. [1]

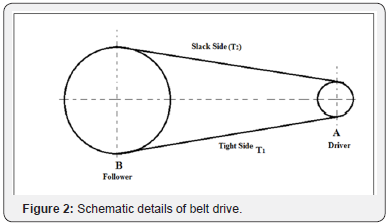

In this study, we discussing about belt drive-open

system of piston-press machine. Belts are used when the distance between

the axes of the two shafts to be connected is considerable. A flat belt

is a belt with a narrow rectangular cross-section. The flat belts are

easier to use and are subjected to minimum bending stress.

In the present paper, the pulley is simulated with

ANSYS 12.0.1 Software. This way the concern of different process

parameters such as coefficient of friction, power, thickness of belt,

slip and tension on belt are studied.

Discussion of various parts

(Figure 1) Briquetting plant consists from various parts. The main part is as follows:

Biomass-grinding machine: It is an important part of the briquetting plant, which function is to convert aggregate material in to small pieces.

Screw conveyor: it is used to carry the raw

biomass from storage place to hopper. It is also used to mix the

moisture socking agent from the raw biomass.

Piston-press machine:

a) Hopper: Hopper is use to move the raw

material from screw conveyor to processing place. It includes extruder

which is used to give a motion to raw biomass only in a one direction.

b) Ram: Ram is used for forcing the raw biomass in a die

holder. Ram is fixed in ram holder. These ram moves in a

horizontal direction with the help of motor.

c) Collar: Collar is use to fix the die in a die holder. Also

it is used for to prevent the flow of raw biomass in a wrong

direction i.e. in motor direction.

d) Die: Die is the part where the briquette get the shape to

from the briquette.

Cooling tower: After process of briquette formation it cool at

cooling tower and move in a direction of storage place. [2]

In piston-press machine all the rotary as well as reciprocating

parts moving through the pulley belt arrangement. Therefore,

pulley belt system is very important part of briquetting plant. In

this study, discussing about pulley and bet system of briquetting

plant (Figure 2).

Aim of Study

The main aim of this study is to investigate:

a) Effects of coefficient of friction (COF)

b) Effect of different Belt thickness (t) on the quality of belt

c) Effect of tension (T) on pulley

d) Effect of slip (s).

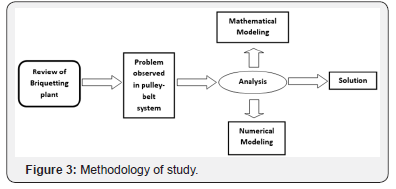

Methodology

(Figure 3)

Input Data

Diameter of Driver d1=0.15 m;

Diameter of Follower d2=0.85m;

Speed of Drier N1=1475rpm;

Speed of Follower N2=?;

Power P=20kW;

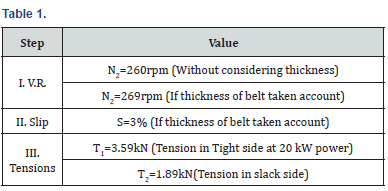

Estimation of tension during rotation of driving pulley

A highly elastic belt is used for belt drive, which is operated by

15 hp electric motor and at the speed of driver & driven pulleys

are 1475rpm & 260rpm, the diameter of driver & follower pulleys

are 150 mm & 850 mm. Center to Center distance is 1.575m (Table

1).

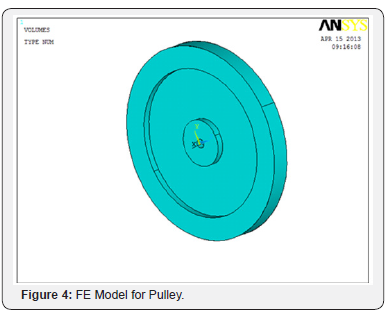

Finite element simulation of pulley: Figure 4 showing FE

model of pulley model prepared in ANSYS 12.0.1.

The 3-D FE model for pulley was created by using ANSYS

12.0.1 software. The shaft is analyzed in ANSYS in three steps.

First is preprocessing which involves modeling, geometric clean

up, element property definition and meshing. Next comes, solution

which involves imposing boundary conditions and applying loads

on the model and then solution runs. Next in sequence comes post

processing, which involves analyzing the results plotting different

parameters like stress, strain, natural frequency, harmonic

frequency and many. The mesh has been generated using tetra

free element. The Solid 45 element type is adopted to mesh the

model. The mesh of the pulley consists of 83198 elements. 17492

nodes are included in the finite element model. [3-5].

Result & Discussion

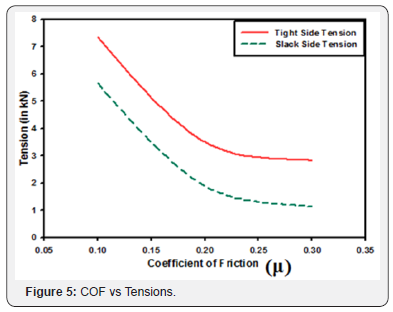

Present study deal with coefficient of friction between belt

and pulley and variation of thickness of belt. The stress analysis

have done through numerical simulation which shown in Figure

5-7.

Figure 5 showing when the coefficient of friction between the

belt and pulley has increase then the value of tension (slack side &

tight side) will decreases. But both line follow same pattern. And

also the 0.2 to 0.3 coefficient of friction will better value between

belt and pulley.

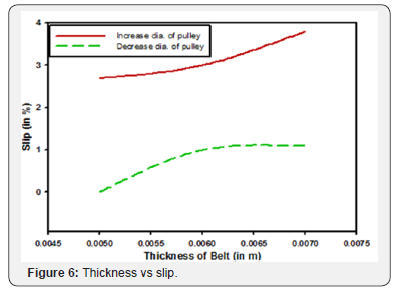

Figure 6 showing when the thickness of belt increases also

with increase of pulley diameter than the slip of belt increases.

But, when the thickness of belt increases also with decrease of

pulley diameter than the slip of belt decreases.

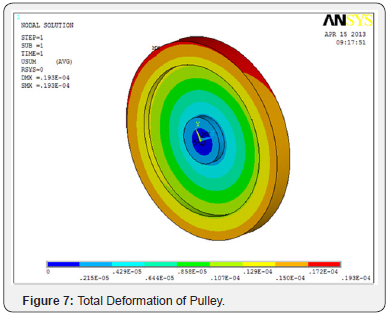

Figure 7 showing pulley simulation of piston-press machine,

this simulation shows the total deformation of pulley. In this figure

value of maximum deformation is 0.193E-04.

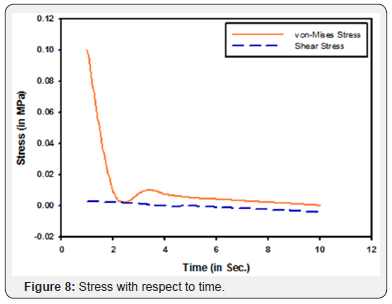

Figure 8 showing that the von-Mises stress and shear stress on

the pulley periphery through simulation.

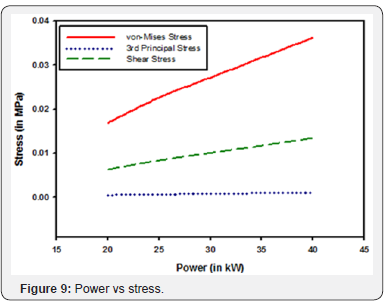

Figure 9 showing simulation results. In this graph of belt

tension has analysed in terms of power. When the belt tight side

tension has increased than the value of stresses (von-Mises stress,

principal stress, shear stress) have follow same pattern, but the

stress will also increasing.

Conclusion

a) Coefficient of friction has play major role in tensions on

belt.

b) Change of belt thickness decrease as well as increase the

slip of belt. Also the change in diameter of pulley affects the

slip of belt.

c) The simulation is easily finding the stress on pulley that

occurs due to belt tension.

For More Open Access Journals Please Click on: Juniper Publishers

For More Articles Please Visit: Robotics & Automation Engineering Journal

Comments

Post a Comment