Novel Configurations of Slit Tubular Soft Robotic Actuators and Sensors made with Ionic Polymer Metal Composites (IPMCs)- Juniper Publishers

Juniper Publishers- Journal of Robotics

Abstract

Reported is a new family of ionic polymer metal

composites (IPMCs) actuators, energy harvesters and sensors in slit

cylindrical/tubular configurations. The slit IPMC cylindrical/tubular

elements are made of bending IPMC slit elements distributed

symmetrically around a cylindrical mantle. The slit bending elements

around the cylindrical mantle may be either straight and/or parallel

with the longitudinal axis of the cylinder for linear actuation and

sensing in terms of the length of the entire cylinder or may be

helically wound around the cylindrical mantle to produce a combination

of linear and torsional actuations and even bending for the slit

cylindrical tube. This paper further introduces some models and special

cases of linear IPMC actuators and sensors in slit cylindrical/tubular

form. Experimental results relating the bending deformation to the axial

deformations of slit cylinders are also presented. Of particular

interest is the emergence of undulating linear actuation and sensing by

slit IPMCs and their combination with twisting and bending to create 3-D

soft robotic manipulation and undulation like in an elephant trunk.

Keywords: Novel Configurations; Slit Tubular; Soft Robotic Actuators; Sensors;Ionic Polymer; Metal Composites

Abbrevations: IPMCs: Ionic Polymer Metal Composites; EAPs: Electro Active Polymers

Introduction

Ionic polymer-metal composites (IPMCs) are synthetic

nanocomposite materials. They belong to the family of electro active

polymers (EAPs). IPMCs deform (actuation mode) in an imposed small

electric field (few kV/m). Also, they generate electrical fields

(sensing/energy harvesting mode) upon physical deformation or via

environmental dynamics, like wind or ocean waves (few mVs for small

samples, 10mm x 40mm x 0.2mm). They work both in air and polar liquids

such as water and blood. In both cases the conjugated cations need to be

mobile enough to migrate towards the cathode when an electric field is

imposed on them. This mobility is generally triggered by the osmotic

pressure created by the migration of hydrated cations. The mobility and

reconfiguration of cations can also be initiated if the IPMCs are in or

under water. To maintain consistency in actuation and sensing the IPMCs

may be encapsulated with thin silicone rubber sheath, by spraying them

with silicone spray to maintain a uniform humidity during actuation,

energy harvesting and sensing operations.

An early coverage and review of IPMCs were first

published in 1998 by Shahinpoor, Bar-Cohen, Xue, Simpson and Smith

[1,2]. However, the original idea of ionic polymer actuators and sensors

goes back to 1992-93time frames and the pioneering work of

Osada, Oguro, Kawami, Asaka, Takenaka and Shahinpoor [3-14]. IPMCs are

composed of an ionic polymer like Nafion® or Flemion® whose surfaces are

chemically plated or physically coated with conductors like platinum or

gold. The electrodynamics of charge migration and generation in these

materials are governed by the Poisson-Nernst-Planck field equations

[15-24]. These materials display artificial muscle behavior under an

applied voltage or electric field. For example an applied voltages of 1

to 4 volts for a typical sample of the size 10mm x 40mm x 0.2mm

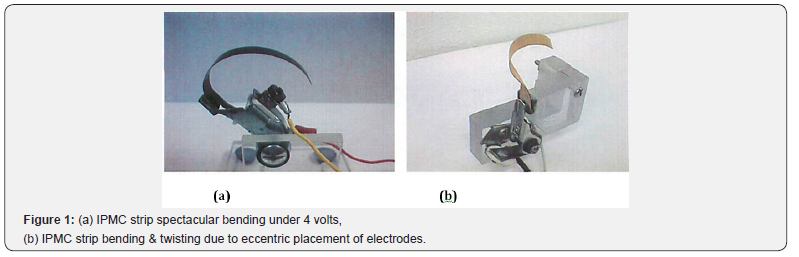

typically produces spectacular bending (Figure 1).

Ions migration and redistribution, due to the imposed

voltage across a strip of IPMC, result in all kinds of deformations. If

the plated electrodes are arranged in a non-symmetric configuration,

the imposed voltage can induce many kinds of deformations such as

twisting, rolling, turning, twirling, whirling and non-symmetric bending

deformation. Alternatively, if such deformations are physically applied

to an IPMC strip they generate a voltage signal (few millivolts for

typical small samples) as sensors and energy harvesters [25-27].

Figure1a & 1bdepict various deformation

configurations of IPMC strips depending on the placement configuration

of the electrodes chemically plated on the IPMCs. Such twisting/bending

deformations of IPMCs (Figure 1b) may be generated by placing

the electrodes on the IPMC strip in eccentric and non-symmetrical

configurations. These materials generate a force density of about

40 in a cantilever configuration for sizes around 5mm x 30mm x

0.2mm, meaning they can generate a tip blocking force of almost

40 times their own weight in a cantilever mode[12,23]. In other

words if the weight of a cantilever is about 0.06 gmf, based on a

density of 2 gm/cm3, the sample can produce a tip blocking force

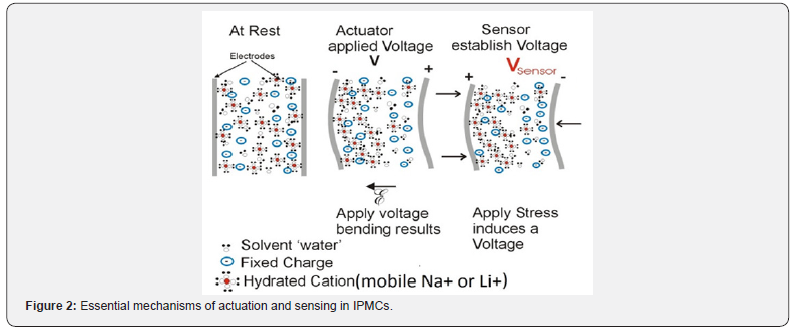

of about 2.4 gmf. Figure 2 displays the actuation and sensing

mechanisms in cantilever strips of IPMCs in a graphical manner.

The essential mechanism for both actuation and sensing/

energy harvesting capabilities of IPMCs is the migration of

hydrated cations (Na+, Li+), which are loosely adjoined to the

underlying molecular network with anions, towards the cathode

electrode and away from the anode electrode due to either an

imposed electric field (actuation) or an imposed deformation field

(sensing/energy harvesting). The cations are generally attached to

a number of water molecules (hydration number) which is about

4 for Na+ and 6 for Li+. These deformations are considered to be

related to contraction due to depletion of cations from the anode

side and osmotic pressure or tension due to arrival of hydrated

cations on the cathode electrodes side due to Poisson-Nernst-

Planck phenomena [23,24]. It is expected that for a typical sample

IPMCs in actuation, sensing and energy harvesting modes there

exists a broad bandwidth (kilo HZ and beyond) for their actuation,

energy harvesting and sensing response to an imposed electric

field or deformation field. The migration of hydrated cations

depends on the structure of the base material (DuPont Nafion®,

Asahi Glass Flemion®) and how uniform the electrodes are plated

on the base material.

In the next section, a brief mathematical model for the

actuation and sensing of IPMC is presented.

IPMC Actuation and Sensing Modeling

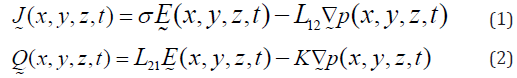

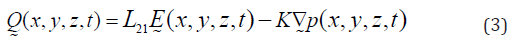

de Gennes and coworkers [15] presented the first

phenomenological theory for sensing and actuation in ionic

polymer metal composites. Asaka et al. [16] discussed the bending

of polyelectrolyte membrane-platinum composites by electric

stimuli and presented a theory on actuation mechanisms in

IPMC by considering the electro-osmotic drag term in transport

equations. Figure 2 clearly displays the mechanisms of actuation

and sensing of IPMCs. Let us now summarize the underlying principle of the Ionic

polymeric nanocomposites actuation and sensing capabilities,

which can be described by the standard Onsager formulation

using linear irreversible thermodynamics. When static conditions

are imposed, a simple description of mechanoelectric effect is

possible based upon two forms of transport: ion transport (with

a current density, , normal to the material) and solvent transport

(with a flux,Q

, we can assume that this term is water flux). The

conjugate forces include the electric field, and the pressure

gradient  . The resulting equation has the concise form

of

. The resulting equation has the concise form

of

. The resulting equation has the concise form

of

. The resulting equation has the concise form

of

Where,σ and K are the material electric conductance and

the Darcy permeability coefficient, respectively. A cross coefficient

(Onsager’s coefficient) is usually symmetric or 12 21 L = L = L . The

simplicity of the above equations provides a compact view of the

underlying principles of actuation, transduction and sensing of

the ionic polymer nanocomposites. When we measure the direct

effect (actuation mode) we work (ideally) with electrodes which

are impermeable to ion species flux, and thus we have = 0. This

simplifies the equations to:

This  will, in turn, induce a curvature k

proportional to

will, in turn, induce a curvature k

proportional to  . The relationships between the

curvature k

and pressure gradient

. The relationships between the

curvature k

and pressure gradient  are fully derived

and described in de Gennes, Okumura, Shahinpoor and Kim [15].

are fully derived

and described in de Gennes, Okumura, Shahinpoor and Kim [15].

will, in turn, induce a curvature k

proportional to

will, in turn, induce a curvature k

proportional to  . The relationships between the

curvature k

and pressure gradient

. The relationships between the

curvature k

and pressure gradient  are fully derived

and described in de Gennes, Okumura, Shahinpoor and Kim [15].

are fully derived

and described in de Gennes, Okumura, Shahinpoor and Kim [15].

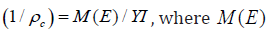

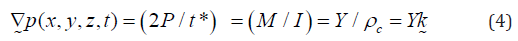

Note that  is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

is the local induced

bending moment and is a function of the imposed electric field

E, Y is the Young’s modulus (elastic stiffness) of the strip which

is a function of the hydration H of the ionic polymer metal

nanocomposite and I is the moment of inertia of the strip. Note

that locally M(E) is related to the pressure gradient such that in a

simplified scalar format [15]:

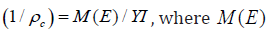

Note that vectorially the curvature  is related to the imposed

electric field E

is related to the imposed

electric field E  Based on this simplified

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].

Based on this simplified

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].

is related to the imposed

electric field E

is related to the imposed

electric field E  Based on this simplified

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].

Based on this simplified

model the tip bending deflection δmax of an IPMC strip of length lg

can be shown to be almost linearly related to the imposed electric

field. The experimental deformation characteristics of IPMCs are

clearly consistent with the above predictions obtained by the

above linear irreversible thermodynamics formulation which

is also consistent with the above equation in the steady state

conditions. Note also that the value of the Onsager coefficient L

has been estimated to be of the order of 10-8m2/V-s [20-24]. Other

parameters have been experimentally measured to be K~10-

18m2/CP, σ ~1A/mV or S/m. On the other hand one may consider

charge transport modeling of actuation and sensing. The reader is

referred to Bahramzadeh and Shahinpoor [20-24] and Shahinpoor

[22-24] for such Poisson-Nernst-Planck equations. Similar to poly (ethylene-co-methacrylic acid) metal composite, member of

the electroactive polymer can be introduced as biomimetic soft

robotic polymer [28-32].Some Experimental Results

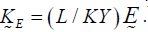

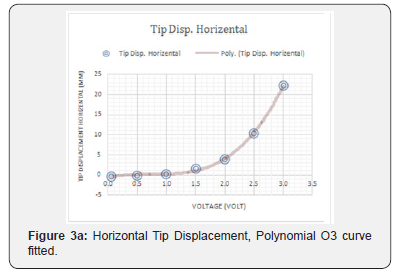

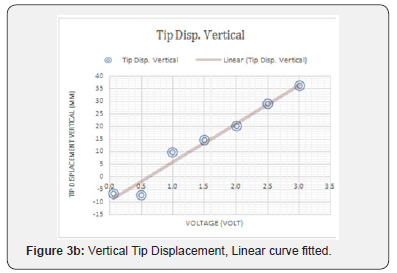

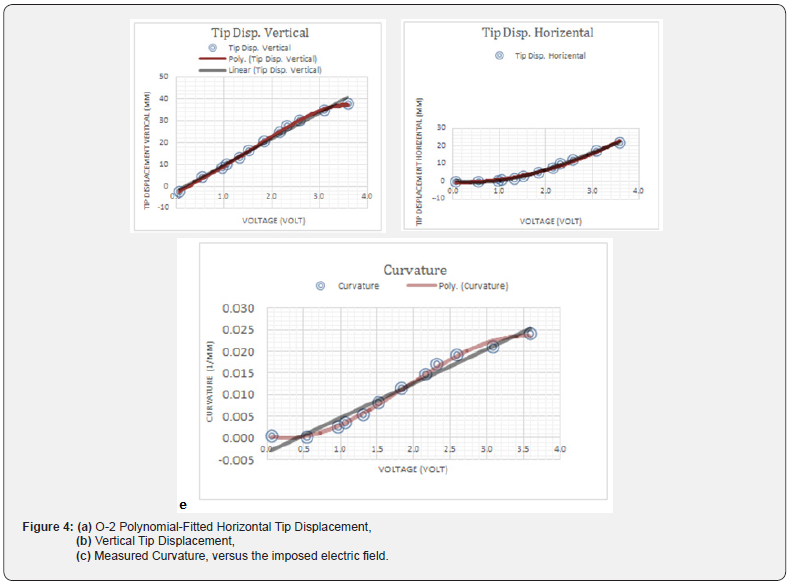

Figures 3(a,b&c) represent experimental results for

deformation (tip displacement and curvature) of a small strip

of slit IPMC (40mm x 12mm x 0.2mm) with simple-supported

ends in a small electric field (under 5 Volts/0.2mm) in horizontal

and vertical directions. For each graph the bestfittedcurve is

constructed to demonstrate the consistency in material response.

Another set of experimental results were obtained and plotted

in connection with slit IPMC strips with built-in ends to recapture

the tip displacements in vertical and horizontal configurations,

as well as curvature. The results for the second test series are

presented in Figure 4(a,b&c).

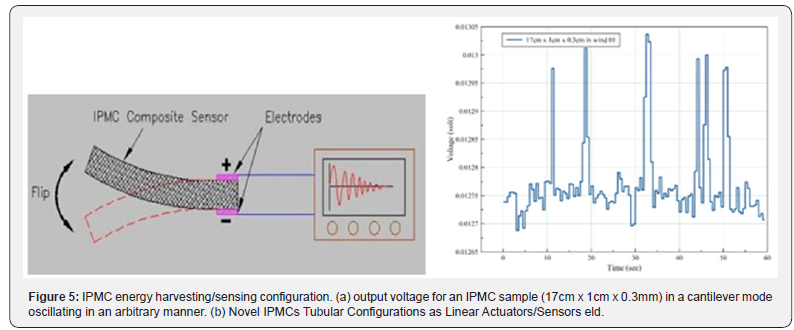

Figure 5(a&b) represents sensing and energy harvesting

characteristics of IPMCs [12,23]. Simultaneous actuation and

sensing of IPMCs are of interest to soft robotic researchers.

Note that IPMCs havea broad range of applicationsin soft

biomimetic robotic actuation, energy harvesting and sensing

[23-24]. In this section some novel configurations for IPMC

actuators and sensors/energy harvesterswill be introduced.

Based on the reported test results in Figure 3&4 for large

deformation and actuation of IPMC materials, it is expected these

novel configurations will be practically useful for engineering

applications.Asimpledescription of actuation in this type of

material is based on cationic migration towards the cathode to

expand the cathode side of IPMC by osmotic pressure and contract

the anode side of the IPMC resulting in bending towards the anode

side as depicted in Figure 2.

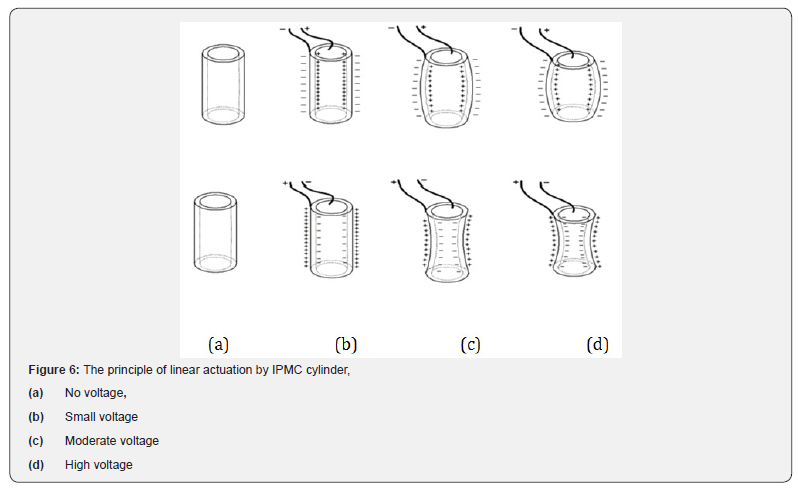

In other cases and configurations, the IPMC sample can be

considered as a non-slit cylinder/tube such that it can act like a

linear actuator and generate an axial force (Figure 6).

In the sensing mode, the axial forces on both ends force

the cylinder to shrink and thus, as a result, the material will

accommodate the deformation. This accommodation can be inward

or outward. The pressure gradient due to this accommodation

will generate the expected signal to sense the displacement [12].

Regarding the buckling instability under axial loading, the non-slit

cylindrical/tubular structures will have initial slight curvature

outward or inward to minimize buckling instabilities. In addition,

from actuation point of view, an applied electric field causes the

non-slit cylinder/tube to contract/expand axially/laterally as

shown in Figure 6, based on the voltage polarity. This applied field

will gradually deform the cylinder to become more like a sphere

(Figure 6d).

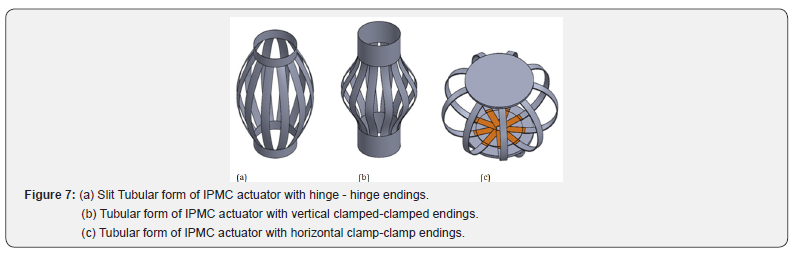

Another case will be using IPMC strips around a cylindrical/

tubular object or a slit tubular IPMC. Some of the configurations

of slit IPMC strips around a cylindrical/tubular mantle are shown

below in Figure 7(a,b&c).

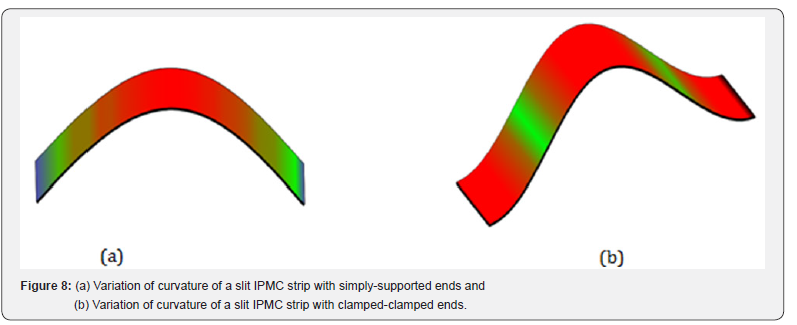

In the slit tubular configurations in Figure 7, slit IPMC

cylindrical strips experience two major forms of boundary

condition for this type of the actuator/sensor family (Hinged in

Figure 8a and clamped in Figure 7(b&c). Other form of boundary

condition will provide more complex manipulation and maneuver

possibilities that will be discussed later. These concept also are

likely to be used for applications in pumps/micro-pumps in which

the pushing or taking in a fluid can be performed by bending/

deformation of the slit strips in which an inner housing should

accompany the assembly. In other word the volume change due to

the movement of the IPMCs will initiate the pumping action.

Regarding the sensing mode, whenfor the slit IPMC strips are

in a hinge-hinge or simply-supported configuration, there will be

less force requirement for the desired displacement andit further

results in generatinghigher output voltage. Further, during sensing

action the effective length of the IPMC strip is longer. Figure 8,

demonstrate the curvature variations related to this formation

such that the red regions are in compression and green regions

are in tension and the green parts are almost straight.

It is also reasonable to note that due to having longer effective

length, the hinged-hinged model will have a larger force capacity

in actuation. The model with clamped ending will have a shorter

effective length to generate output signal and requires a higher

level of voltage to operate.

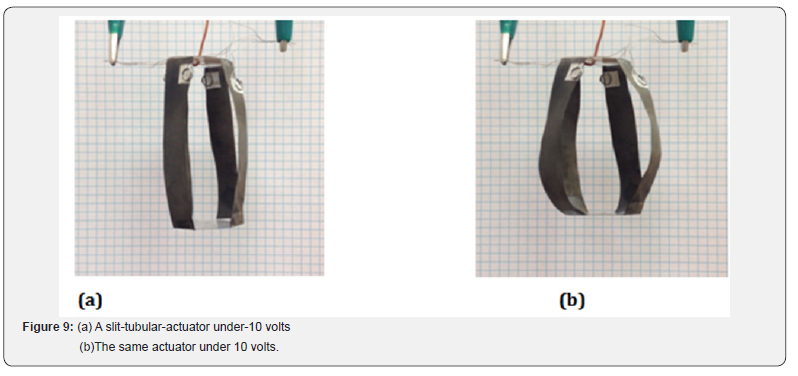

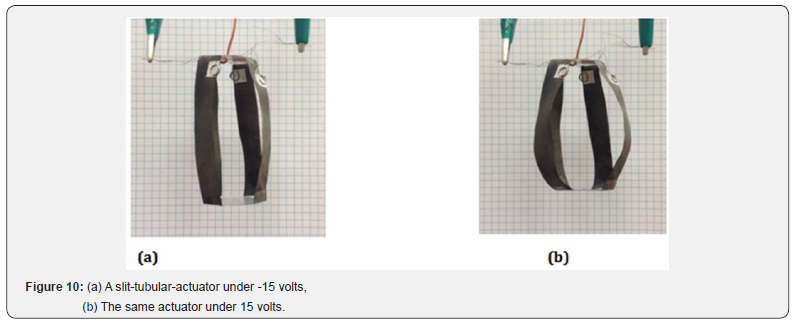

Figure 9 depict a simple form of slit IPMC cylinders in straight

simple pinned ending format (Figure 10).

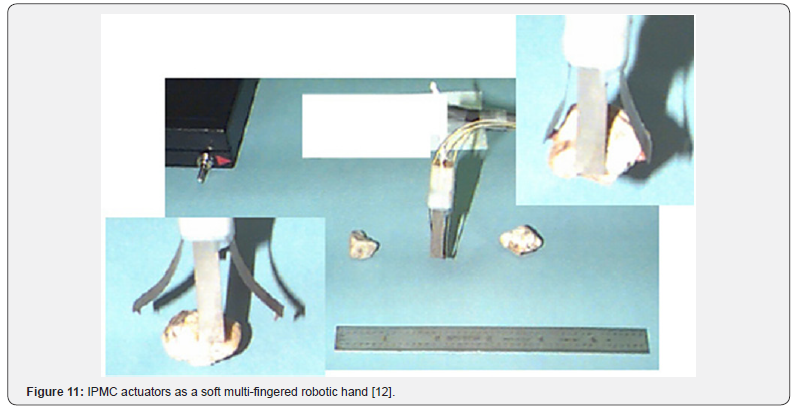

Some variations of these slit cylindrical configurations have

been introduced previously by Yeom and Oh [30], Kamamichi [31]

and Shahinpoor [23,24] in connection with jellyfish swimming

and multi-fingered soft robotic grippers, Figure 11.

In case of attaching the platform to an arm, these legs can act

like multi-fingered soft biomimetic robotic grippers to grasp and

manipulate objects.Other configurationswere also discussed by

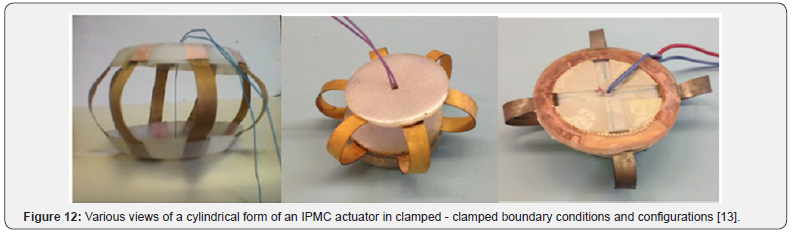

Shahinpoor and Kwang [13], as shown in Figure12

The hinged-hinged configuration will help this possibility in

a more efficient way to have longer actuation range.The bending

for sensing is generally outward rather than inward because the

slit IPMC strips considered are initially slightly bent outward to

prevent any buckling instability.

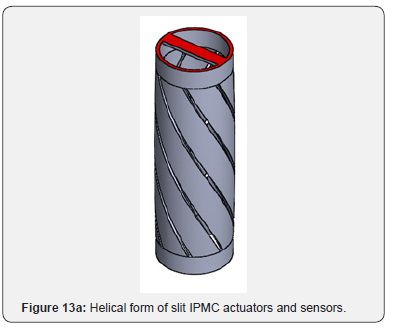

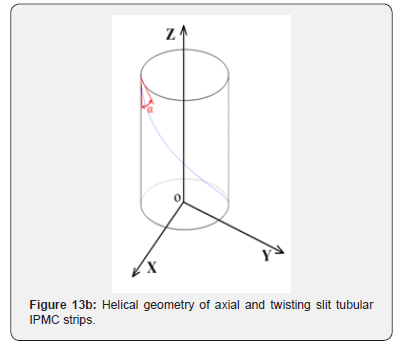

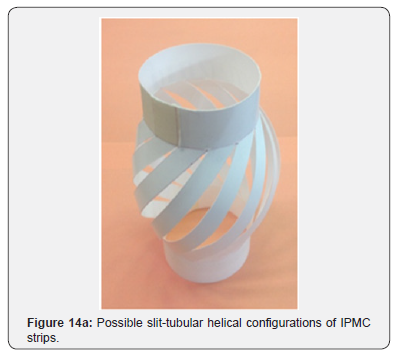

From another point of views, slits on cylindrical configuration

can be at an angle to introduce the helically twist and sloped

version of helical form of IPMC shown in Figures 13(a&b). This

configuration of helically slit IPMC strips will generate axial and

twisting motion upon actuation and yet it produces electricity

once axially squeezed. Here since the twisting and retracting are

related to each other, the model is considered to be more like an

actuator.

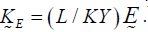

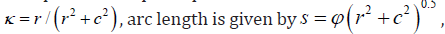

These configurations of slit IPMC strips produces twisting and

linearly moving actuators similar to an automated drill/screw

driver. Note that the helical IPMC actuator/sensor slit strips are like

space curves with coordinates x, y and z such that x = r cosϕ y = r sinϕ and z = c ϕ for ϕ[0,2π] 2π ]where r is the radius of

the helix and c is a constant giving the vertical separation of the

helix’s loops and ϕ is an independent parameter. The tan α= c/r

is slop of the strip sample. The curvature of the helix is given by  torsion

of a helix is given by

torsion

of a helix is given by

torsion

of a helix is given by

torsion

of a helix is given by

Some studies and modeling for the types of combined linear/

twisting actuators reported in this paper have been proposed by

Li and Kim [32] and Moeinkhah and Rezaeepazhand [33] and

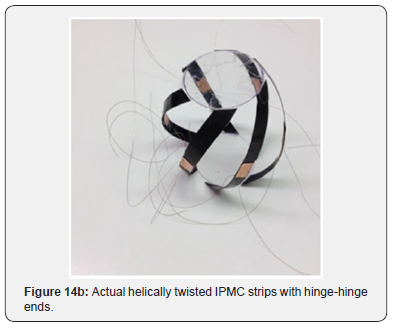

others. Figure 14(a, b&c) depictvarious configurations of helical

assembly of slit tubular IPMCs for actuation, energy harvesting

and sensing with more geometric complexitiesare currently under

investigations and will be reported later

Soft Robotics Snake-Like Configurations Based on Linear-Torsional IPMC Actuators/sensors

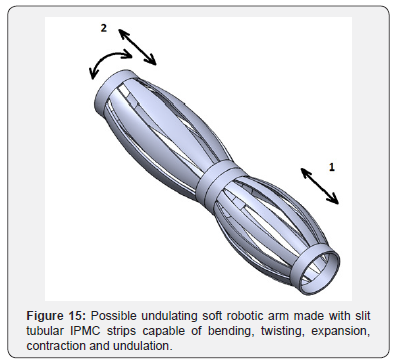

Here the initial form of the device considered for the

tubularactuators/sensors is a combination of axial and rotary

movements that resembles slithering snakes,as shown in Figure

15 below:

In Figure 15 note that by a combination of movements 1 and 2,

the device is capable of 3-D undulating anobject like an elephant

trunk or a slithering snake-like flexible robotic manipulator [30].

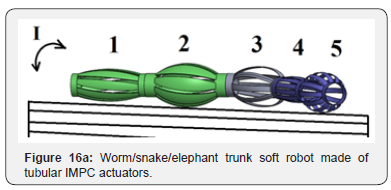

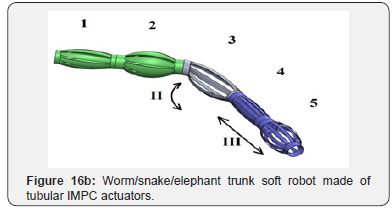

Referring to Figure 16, in case of having more combination of these

actuations configuration, possibility of having a more complex

robot can be expected as it is depicted in Figure 16

In Figure16 (a&b) a variety of control and boundary condition

can be applied to the assembly to move the soft snake-like, wormlike

or elephant trunk-like soft robots. For the rotary movement

in the direction denoted by I, actuators 1 and 2 are helically

arrangedand can produce a combined rotation and slithering

movement. The actuator number 3 in Figure 16b enables bending

and twisting due to having unsymmetrically applied voltages to

generatehelical and planar movements in the direction denoted

by II. Yet extensional movements can be achieved by actuator 3

in Figure 16b in the direction denoted by III. Thus, we conclude

that combination of cylindrically and helically arranged IPMC

actuators are capable of generating elephant-trunk like motion.

Conclusion

A new family of IPMC linear actuators and sensors in the form

of a slit tubular structure was introduced and discussed. These

groups of actuator and sensors were considered to be made with

bending/twisting slitIPMC elements symmetrically distributed

around a cylindrical/tubular mantle. These types of soft actuators

and sensors are capable of generating a combination of actuation,

energy harvesting and sensing consisting of linear expansion,

contraction, bending, twisting and rotating action similar to a

slithering snake or an elephant trunk.Theslit bending elements

around the tubular mantle were designed to be straight and parallel

with the longitudinal axis of the cylinder for pure linear actuation

and sensing in terms of the length of the entire cylinder. However,

the possibility of helically winding the bending elements around

the cylindrical mantle to produce a combination of linear and

torsional actuation and bending for the cylinder was also briefly

discussed. This introduction of linear/torsional actuation/energy

harvesting and sensing opens the possibility for introducing new

family of soft biomimetic robotic actuators and sensors. The

next steps in development of advanced elephant-trunk-like soft

biomimetic robotic actuators and sensors are to further explore

various cylindrically and helically arranged IPMC strips. Currently,

we are further exploring such possibilities towards fabrication an

elephant-trunk type soft robot.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Robotics & Automation Engineering Journal

Comments

Post a Comment