Modelling and Simulation of AGVs Using Petri Nets- Juniper Publishers

Juniper Publishers- Journal of Robotics

Introduction

It is a technologically anticipated development that

robotics in our age will become widespread and find common application

areas in almost all sectors such as defense, transportation, health,

service and manufacturing. This process is still expanding and the role

of robots in everyday life as well as in industrial applications is

increasing. One of the important applications of robotic systems in

manufacturing environments is automated guided vehicles (AGVs). AGVs are

autonomous systems controlled by a central control unit, operate

autonomously without the need for an operator, and are used for

transporting materials from one point to another [1-3]. An AGV reduces

the number of occupational accidents that occur due to human beings

because it fulfills all kinds of transportation operations without human

interference in departments such as production, logistics, warehouse

and distribution. These systems, which are used to transport all kinds

of goods in industrial environments, are one of the most suitable

systems to reduce costs and increase productivity. The AGVs can see the

obstacles in their way due to the highest level of security measures

used and sensors, slow down and stay at a safe distance. So, they can

work safely in the same environment with people. Because of all these

features and modularity, AGVs are frequently used in modern and flexible

manufacturing systems today.

AGVs carrying products/parts/materials between

workstations are controlled by their own (embedded) computers/processors

and they are connected to the central computer. The design and

operation of AGVs, which are quite complex and expensive systems, are of

great importance for achieving high performance in their use. AGVs,

which are finding increasingly more application areas and capable of

carrying tasks at different scales in various environments, are today’s

one of the major mobile robotic systems. For this reason, modeling and

simulation of behavior of AGVs in working environments is of great

importance and one of the most powerful tools for behavioral modeling of

AGVs is Petri nets. Petri net is a bi-partite mathematical and

graphical formalism consisting of place, transitions and arc as main

constructs. Generally, places

represent resources, transitions transformations and tokens holding of

conditions, but any concept can be assigned to constructs depending upon

modelling approach. Petri net can be used to model discrete event

dynamical systems (DEDS) [4-8]. Petri net has the capability to model

and analyze a discrete event dynamical system (DEDS) and an AGV embedded

in a flexible manufacturing system is a good candidate to qualify for

implementation of Petri net method. This paper summarizes two research

studies for modelling, simulation and analysis of AGV behaviors using

Petri nets. One of them is a Petri net model for the intended behavior

of a demonstrative AGV for transferring packs between stations in a

pre-defined manufacturing environment. The second is a Coloured Petri

net model of a loop layout automated guided vehicle system embedded in

an automated manufacturing system.

Petri Net Based Behavioural Simulation of a Pick Packing AGV

Petri net is used in our behavioural modelling and

simulation study for a demonstrative pick packing AGV as an

implementation of systematic behaviour-based design approach [9]. The

AGV is considered as required to transfer some packs between four

stations in a pre-defined environment. A Petri Net model for the

intended behaviour with three pre-specified missions is developed based

on rough conceptual structuring of the AGV. Model development and

simulation has been done successfully using Artifex modelling and

simulation environment [10,11].

The general design requirement in the present case

study is considered as the conceptualization of an AGV model to transfer

some packs between finite number of stations and therefore, the

required system is called as a “pick packing AGV”. The operational

behaviour of the pick packing AGV is based on a scenario and it is

described as follows: The AGV will be able to travel in a predefined

physical environment between a “Start Point” and four stations, and to

transfer some packs between these stations. The AGV is expected to

accomplish predefined missions without any external interference. A

Petri Net model used to represent and simulate the intended behaviour of

the

pick packing AGV. The model is developed using ArtifexTM

Graphical Modelling and Simulation Environment which a

C-based development platform for discrete event simulation.

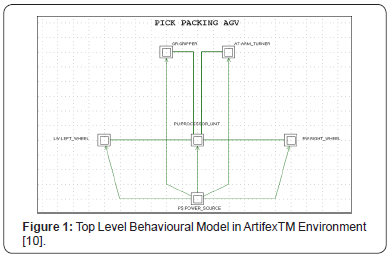

Figure 1 shows the Top-Level Behavioural Model of the AGV in

the ArtifexTM environment. The Top-Level Behavioural Model

consists of six objects, namely units, which are Power Source

and Processor Units, Right and Left Wheel Units, Robot Arm

Unit and Gripper Unit. All units are connected to each other by

interconnecting links that models the communication between

these units. Petri Net structure of each unit is embedded in the

top-level model.

Modelling and Analysis of AGV for an Automated Manufacturing System using Coloured Petri Nets

A loop layout automated guided vehicle system embedded

in an automated manufacturing system has been modelled

and analyzed by applying colored Petri net method. This study

focused at developing of automated guided vehicle system

for serving a flexible manufacturing system comprising of

six workstations arranged in a loop layout. AGVs are serving

workstations moving sequentially in a loop layout. AGVS

has been modelled and analyzed using Petri net method,

specifically using color Petri net class implemented by CPN

Tools. Modelling and analysis have been extended in this

study by developing a lab scale prototype of an AGV which

has been experimentally tested and verified in an automated

manufacturing system. Simulation experiment results have

been validated by developing and employing an AGV prototype

inside an automated manufacturing system. The results

show that an increase in number of AGVs in an automated

manufacturing system increases system throughput whereas

an increase in AGV speed, for a fixed number of AGVs in the

system, is causing a decrease in throughput. The approach

developed in this study can be employed to different system

configurations to determine system performance.

Conclusion

As AGV systems find more application areas in industry,

their modelling and simulation becomes more significant for

industrial system design. Petri net tools are practical and

highly useful tools to study and develop model design before

expensive implementation. It is highly versatile at moderate

sophistication and reasonably reliable output. A physical

prototyping after modelling and simulation would be highly

useful to foresee any probable problem location within the

system before full scale testing. It is also a highly efficient

approach for educational purposes at graduate levels.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Robotics & Automation Engineering Journal

Comments

Post a Comment