Geometric Simulation for 3D-Printed Soft Robots- Juniper Publishers

Juniper Publishers- Journal of Robotics

Introduction

Robots fabricated by soft materials can provide

higher flexibility and thus better safety while interacting with natural

objects with low stiffness such as food and human beings. With the

growth of three-dimensional (3D) printing, it is even possible to

directly fabricate soft robots [1,2] with complex structures and

multiple materials realizing highly dexterous tasks like

human-interactive grasping and confined area detection [3]. However,

with such increased degrees of freedom (DoF), the design of soft robots

becomes a very difficult task. It can be made possible by integrating

simulation into the design phase. However, the shape deformation comes

from many different and complex factors including manufacturing process,

material properties, actuation, etc. Especially with the limited

understanding of layer-based additive process in AM, it is challenging

to formulate a complete mathematical model for the simulation.

SOFA [4] is one of the most widely used frameworks

for physical simulation. It is also applied in the simulation of soft

robots that supports interactive deformation [5]. However, it may suffer

from the problem of numerical accuracy, particularly

if there is large deformation. Unfortunately, one benefit of soft robot

is its capability of adapting to highly curved contact by large

deformation, which needs to be precisely simulated for many

applications. There is another type of simulation methodology to

simplify the simulation model of deformation to a geometry optimization

problem [6]. It was originally developed in the computer graphics area

for visualization, but it has been proved to work superbly in physical

simulation like self-transformation structures [7] and the computational

efficiency is remarkable [8]. This geometric simulation is particularly

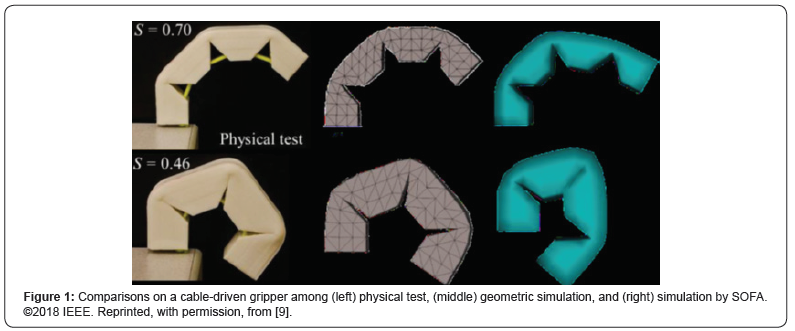

suitable for soft robots [9] (Figure 1), because the actuation of soft

robots is commonly defined by geometry variations (e.g., cable

shortening and pneumatic expansion), and it is actually indirect to

first obtain apply them in the conventional deformation simulation. It

is shown that the geometric simulation gives better convergence and

accuracy than the conventional methods. Therefore, the aim of this

review is to share this technique with a broader audience in the robotic

community, and discuss the potentials capabilities, and future works of

this technology.

Geometric Simulation

The common way of Finite Element Analysis (FEA) is to apply

Hooke’s law to each element and then assemble the equations to compute the deformation with the applied force:

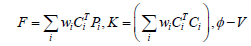

where 𝐹 is the global nodal force vector, 𝐾 is

the global stiffness matrix, and 𝛷 is the global nodal displacement

vector. In the geometric simulation, the formulation is developed by

shape projection on the elements in terms of point positions:

where 𝐕 ∈ ℛ𝑛×3 stacks all the point positions of

𝑛 vertices, Ci ∈

ℛ𝑒×𝑛 is the centering matrix for the 𝑖-th element among 𝑒 elements,

Pi ∈ ℛ 𝑒×3 is the variables defining the shape projections for the

element, and 𝑤𝑖 is the weight for the element, which is commonly

set as the volume. This minimization can be solved by taking

derivative and thus a sparse symmetric positive definite system:

This geometric optimization is formulated to minimize the

elastic energy with reference to shape variations similar to the

physical phenomenon during deformation. To compare Eq. (3)

with Eq. (1), they have the same form with:

Therefore, the geometric simulation actually has the

benefits

as the FEA, but it should be noted the force vector 𝐹 here is defined

purely by the shape projections. As a result, this is a direct

approach to take the geometric actuation as input and compute

the deformed shape of soft robots by numerical optimization using

a geometry-based algorithm. To complete the formulation, the

shape projections should be carefully defined to model different

actuations in the simulation and to model the material properties

geometrically. In the state-of-the-art work [9], the geometric

constraints of actuations are modeled as a type of element, e.g.,

aligning the cable with the edge of elements and shorten the edges,

or scaling the size of elements for volume expansion in pneumatic

actuations. In such way, the actuation can be directly integrated in

the optimization without additional

computation burdens. In terms of modeling the material

properties geometrically in the framework, a calibration step is

done to learn the relationship between material properties and

shape parameters between hard and soft assignments. Should the

element be rigid or preserve its volume is determined by the shape

parameters and modeled by the shape projection. It is shown that

the calibration method can be used to simulate the deformation

of objects with two materials. Different from using constrained

nonlinear optimization, the geometry optimization can converge

in a few iterations, thanks to the shape projection operator.

Discussion

The development of geometric simulation was motivated

by the observation that most actuations of soft robots such as

length shortening of cable and volume changing of chamber

are based on geometry variation. The geometric optimization

tries to preserve shape during deformation with the function of

representing actuations as different type of geometric constraints

to be imposed on specially designed elements. It shows promising

results in terms of accuracy and efficiency, and it is also shown to

be possible in the dynamic models [10].

Conclusion

The preliminary results of the geometry-based framework

are attractive, and its efficiency opens the opportunity of iterative

design for soft robot. However, the current development is

still limited with simple structures, materials, and actuations.

Therefore, to make this simulation more practical and user

friendly, the future works should include extending to different

actuations such as thermo, magnetism or electro ones; multiple

actuations acting together; multiple materials; non-linear material

like hyperplastic material [11]; and multiple bodies with collision

detections.

Comments

Post a Comment