The Review of Reliability Factors Related to Industrial Robo- Juniper Publishers

Juniper Publishers- Journal of Robotics

Abstract

Although, the problem of industrial robot reliability

is closely related to machine reliability and is well known and

described in the literature, it is also more complex and connected with

safety requirements and specific robot related problems (near failure

situations, human errors, software failures, calibration, singularity,

etc.).Compared to the first robot generation, the modern robots are more

advanced, functional and reliable. Some robot’s producers declare very

high robot working time without failures, but there are fewer

publications about the real robot reliability and about occurring

failures. Some surveys show that not every robot user has monitoring and

collects data about robot failures. The practice show, that the most

unreliable components are in the robot’s equipment, including grippers,

tools, sensors, wiring, which are often custom made for different

purposes. The lifecycle of a typical industrial robot is about 10-15

years, because the key mechanical components (e.g. drives, gears,

bearings) are wearing out. The key factor is the periodical maintenance

following the manufacturer’s recommendations. After that time, a

refurbishment of the robot is possible, and it can work further, but

there are also new and better robots from modern generation.

Keywords: Industrial robot;Reliability; Failures; Availability; Maintenance; Safety; MTTF; MTBF; MTTR; DTDTRF

Introduction

Nowadays, one can observe the increasing use of

automation and robotization, which replaces human labor. New

applications of industrial robots are widely used especially for

repetitive and high precision tasks or monotonous activities demanding

physical exertion (e.g. welding, handling). Industrial robots have

mobility similar to human arms and can perform various complex actions

like a human, but they do not get tired and bored. In addition, they

have much greater reliability then human operators. The problem of

industrial robot reliability is like machine reliability and is well

known and described in the literature, but because of the complexity of

robotic systems is also much more complex and is connected with safety

requirements and specific robot related problems (near failure

situations, hardware failures, software failures, singularity, human

errors etc.). Safety is very important, becausethere were many accidents

at work with robots involved, and some of them were deadly. Accidents

were caused rather more often by human errors than by failures of the

robots.

The research about robot reliability was started in

1974 by Engleberger, with publication, which is a summary of three

million hours of work of the first industrial robots–Unimate[1]. A very

comprehensive discussion over the topic is presented by Dhillon in the

book, which covers the problems of robot reliability and safety,

including mathematical modelling of robot reliability and

some examples[2]. An analysis of publications on robot reliability up to

2002 is available in Ref. Dhillon et al.[3], and some of the important

newer publications on robot reliability and associated areas are listed

in the book [4].The modern approach to reliability and safety of the

robotic system is presented in the book, which includes Robot

Reliability Analysis Methods and Models for Performing Robot Reliability

Studies and Robot Maintenance[5]. The reliability is strongly connected

with safety and productivity, therefore other researches include the

design methods of a safe cyber physical industrial robotic manipulator

and safety-function design for the control system or simulation method

for human and robot related performance and reliability[6-7]. There are

fewer publications about the real robot reliability and about occurring

failures [8]. The surveyshows that only about 50 percent of robot users

have monitoring and collect data about robot failures.

Failure analysis of approximately 200 mature robots

in automated production lines, collected from automotive applications in

the UK from 1999, is presented in the article, considering Pareto

analysis of major failure modes. However, presented data did not reveal

sufficiently fine detail of failure history to extract good estimates of

the robot failure rate[9-10].

In the article11. Sakai et al.[11], the results of

research about robot reliability at Toyota factory are presented. The

defects of 300 units of industrial robots in a car assembly line were

analyzed, and

a great improvement in reliability has been achieved. The authors

consider as significant activities that have been driven by robot

users who are involved in the management of the production line.

Nowadays, robot manufacturers declare very high reliability of

their robots [12]. The best reliability can be achieved by the robots

with DELTA and SCARA configuration. This is connected with lower

number of links and joints, compared to other articulated robots.

Because each additional link with serial connection causes an

increase of the unreliability factors, therefore, some components

are connected parallel, especially in the Safety Related Part of the

Control System (SRP/CS), which have doubled number of some

elements, for example emergency stops. Robots are designed in

such way that any single, reasonably foreseeable failure will not

lead to the robot’s hazardous motion [13].Modern industrial

robots are designed to be universal manipulating machines, which

can have different sort of tools and equipment for specific types of

work. However, the robot’s equipment is often custom made and

may turn out to be unreliable as presented in, therefore, the whole

robotic system requires periodic maintenance, following to the

manufacturer’s recommendations [14-15].

operators and robots in cooperative tasks, therefore, the safety

plays a key role. Safety can be transposed in terms of functional

safety addressing the functional reliability in the design and

implementation of devices and components that build the robotic

system [16].

Robot Reliability

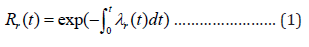

The reliability of objects such as machines or robots is defined

as the probability that they will work correctly for a given time

under defined working conditions. The general formula for

obtaining robot reliability is [2]:

Where:

Rr(t) is the robot reliability at time t,

λr(t) is the robot failure rate.

In practice, for description of reliability, in most cases the

MTTF (Mean Time to Failure) parameter is used, which is the

expected value of exponentially distributed random variable with

the failure rate λr [2].

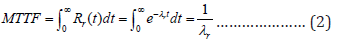

In real industrial environments, the following formula can be

used to estimate the average amount of productive robot time,

before robot failure [2]:

Where:

PHR – is the production hours of a robot,

NRF – is the number of robot failures,

DTDTRF – is the downtime due to robot failure in hours,

MTTF – is the robot mean time to failure.

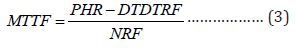

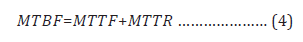

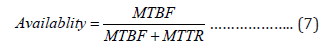

In the case of repairable objects, the MTBF (Mean Time

Between Failures), and the MTTR (Mean Time to Repair)

parameters, can be used.

The reliability of the robotic system depends on the reliability

of its components. The complete robotic workstation includes:

A. Manipulation unit (robot arm),

B. controller (computer with software),

C. equipment (gripper, tools),

D. workstation with workpieces and some obstacles in the

robot working area,

E. safety system (barriers, curtains, sensors),

F. human operator (supervising, set up, teaching,

maintenance).

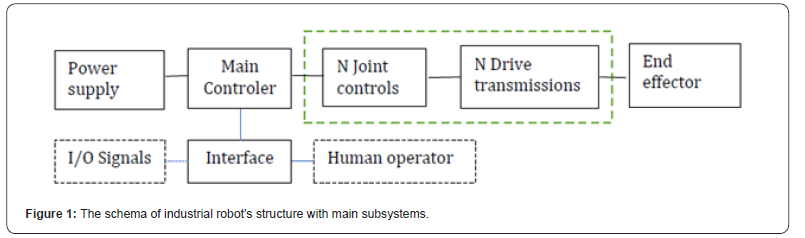

The robot system consists of some subsystems that are

serially connected (as in the Figure 1) and have interface for

communication with the environment or teaching by the human

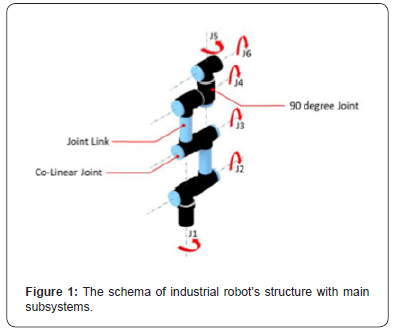

operator.The robot arm can have different number of links and

joints N. Typical articulated robots have N=5-6joints as in the

Figure 2, but more auxiliary axes are possible.

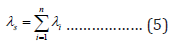

For serially connected subsystems, each failure of one

component brings the whole system to fail. Considering complex

systems, consisting of n serially linked objects, each of which has

exponential failure times with rates λi, i= 1, 2, …, n, the resultant

overall failure rate λSof the system is the sum of the failure rates of

each element λi[2]:

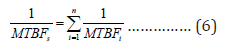

Moreover, the system MTBFS is the sum of inverse MTBFi, of

linked objects:

There are different types of failures possible:

A. Internal hardware failures (mechanical unit, drive, gear),

B. Internal software failures (control system),

C. External component failures (equipment, sensors,

wiring),

D. Human related errors and failures that can be:

a. Dangerous for humans (e.g. unexpected robot

movement),

b. Non-dangerous, fail-safe (robot unable to

move).

Also possible are near failure situations and robot related

problems, which require the robot to be

stopped and human intervention is needed (e.g. recalibration,

reprograming).Because machinery failures may cause severe

disturbances in production processes, the availability of means

of production plays an important role for insuring the flow of

production. Inherent availability can be calculated with the

formula 7 [2].

For example, the availability of Unimate robots was about 98

% over the 10-years period with MTBF=500h and MTTR=8 hours

[2].

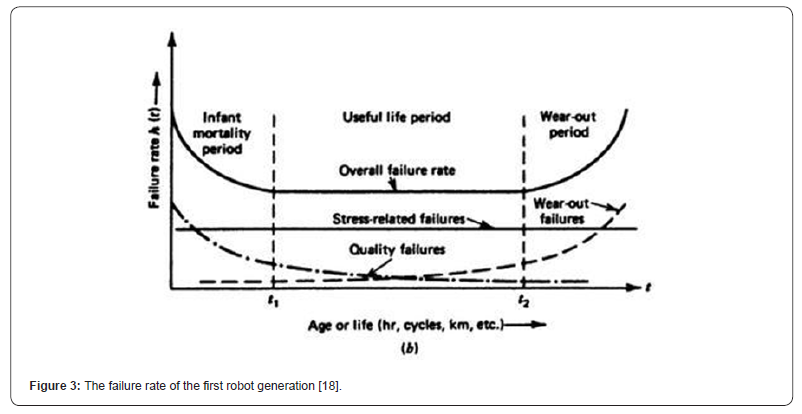

The reliability of the first robot generation represents the

typical bathtub curve (as in Figure3), with high rate of early

“infant mortality” failures, the second part with a constant failure

rate, known as random failures and the third part is an increasing

failure rate, known as wear-out failures (it can be described with

the Weibull distribution).

Therefore, the standard [17] was provided, in order

to minimize testing requirements that will qualify a newly

manufactured (or a newly rebuilt industrial robot) to be placed

into use without additional testing. The purpose of this standard

is to provide assurance, through testing, that infant mortality

failures in industrial robots have been detected and corrected

by the manufacturer at their facility prior to shipment to a user.

Because of this standard, the next robot generation has achieved

better reliability, without early failures, with MTBF about 8000

hours [16].In the articleSakai&Amasaka[11], the results of

research about robot reliability at Toyota are presented. Great

improvement was achieved with an increase of the MTBF to about

30000 hours.

Nowadays, robot manufacturers declare an average of MTBF =

50,000 - 60,000 hours or 20 - 100 million cycles of work [12]. The

best reliability is achieved by the robots with SCARA and DELTA

configuration. This is connected with lower number of links and

joints, compared to other articulated robots.Some interesting

conclusions from the survey about industrial robots conducted in

Canada in year 2000 are as follows [9]:

A. Over 50 percent of the companies keep records of the

robot reliability and safety data,

B. In robotic systems, major sources of failure were

software failure, human error and circuit board troubles from

the users’ point of view,

C. Average production hours for the robots in the Canadian

industries were less than 5,000 hours per year,

D. The most common range of the experienced MTBF was

500–1000h (from the range 500-3000h)

E. Most of the companies need about 1–4h for the MTTR of

their robots (but also in many cases the time was greater than

10h or undefined).

The current industrial practice show that the most unreliable

components are in the robot’s equipment, including grippers,

tools, sensors, wiring, which are often custom made for different

purposes. This equipment can be easily repaired by the robot

user’s repair department. But the failure of critical robot

component requires intervention of the manufacturer service and

can take much more time to repair (and can be counted in days).

Therefore, for better performance and reliability of the robotic

system, periodic maintenance is recommended.

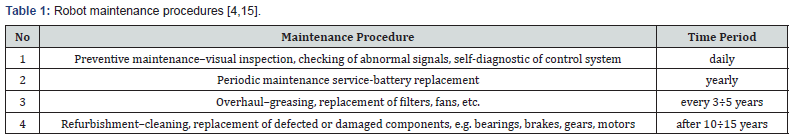

Robot Maintenance

Three basic types of maintenance for robots used in industry

are as follows [4]:

Preventive maintenance

This is basically concerned with servicing robot system

components periodically (e.g. daily, yearly. …)

Corrective maintenance

This is concerned with repairing the robot system whenever

it breaks down.

Predictive maintenance

Nowadays, many robot systems are equipped with

sophisticated electronic components and sensors; some of them

are capable of being programmed to predict when a failure

might happen and to alert the concerned maintenance personnel

(e.g. self-diagnostic, singularity detection).Robot maintenance

should be performed, following to the robot manufacturer’s

recommendations, which are summarized in the Table 1[15].

Preventive maintenance should be provided before each automatic

run, including self-diagnostic of the robot control system, visual

inspection of cables and connectors, checking for oil leakage or

abnormal signals like noise or vibrations. The replacement of the

battery, which powers the robot’s positional memory, is needed

yearly. If the memory is lost, then remastering (recalibration,

synchronization) is needed.Replenishing the robot with grease

every recommended period is needed to prevent the mechanical

components (like gears) from wearing out. Special greases are

used for robots (e.g. Moly White RE No.00) or grease dedicated for

specific application like for the food-industry. Every 3-5 years a

fully technical review (overhaul) with replacement of filters, fans,

connectors, seals, etc. is recommended.

Performing daily inspection, periodic inspection, and

maintenance can keep the performance of robots in a stable state

for a long period. The lifecycle of typical robot is about 10-15

years, because the wear of key mechanical components (drives,

gears, bearings, brakes) causes backlash and positional inaccuracy.

After that time a refurbishment of the robot is possible, and it can

work further for long time. Refurbished Robots are also called remanufactured,

reconditioned, or rebuilt robots.

Conclusion

Nowadays modern industrial robots have achieved high

reliability and functionality;therefore, they are widely used. This is

confirmed by more than one and half million of robots working

worldwide. According to the probability theory, in such large

robot population the failures of some robots are almost inevitable.

The failures are random, and we cannot predict exactly where

and when, they will take place. Therefore, the robot users should

be prepared and should undertake appropriate maintenance

procedures. This is important, because industrial robots can highly

increase the productivity of manufacturing systems, compared to

human labor, but every robot failure can cause severe disturbances

in the production flow,therefore periodic maintenance is required,

in order to prevent robot failures. High reliability is also important

for the next generation of collaborative robots, which should work

close to human workers, and safety must be guaranteed without

barriers. Also, some sorts of service robots, which should help

nonprofessional people (e.g. health care of disabled people)

must have high reliability and safety. There have already been

some accidents at work, with robots involved, therefore, the

next generation of intelligent robots should be reliable enough

to respect the Asimov’s laws and do not hurt people, even if they

make errors and give wrong orders.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Robotics & Automation Engineering Journal

Comments

Post a Comment